Indian Journal of Science and Technology

Year: 2020, Volume: 13, Issue: 23, Pages: 2345-2354

Original Article

Tarikul Islam1, Md Rezaul Karim2, Mehedi Hasan Chaion1, Shubhajit Dutta2, Md Alamgir Hossain2

1Department of Textile Engineering, Jashore University of Science and Technology, Jashore, 7408, Bangladesh

2Department of Textile Engineering, Port City International University, Chittagong-4202, Bangladesh

*Corresponding author

Email: [email protected]

Received Date:12 April 2020, Accepted Date:10 May 2020, Published Date:07 July 2020

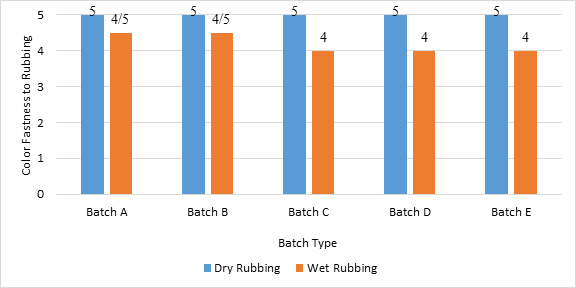

Objectives: The objective of the study is to analysis the effect of chemicals on different physical properties and color fastness of treated cotton samples with standard rating values. Methodology: Five single baths are used for the pretreatment process with five different dosages such as 1g/L, 1.5 g/L, 2 g/L, 2.5 g/L, 3 g/L of NaOH and H2O2. After that, reactive dyeing was performed for these five samples with a standard recipe. Findings: With the gradual increment of NaOH and H2O2 dosages, the absorbency and whiteness index of pretreated samples were improved and for that particular reason bursting strength was degraded. On the other hand, for dyed samples, a little variation was observed in color fastness to wash and rubbing but the changes in the color shade of every sample were observable.

Keywords: Bleaching; color fastness; physical properties; scouring; shade variation

© 2020 Islam, Karim, Chaion, Dutta, Hossain. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.