Indian Journal of Science and Technology

DOI: 10.17485/IJST/v15i48.2158

Year: 2022, Volume: 15, Issue: 48, Pages: 2765-2776

Original Article

Zeenath Fathima Syed1, T R Tamilarasan2*, S Rasool Mohideen1, S M Sanjana3

1Department of Mechanical Engineering, B.S.Abdur Rahman Crescent Institute of Science and Technology, Chennai, 600048, Tamil Nadu, India

2Department of Automobile Engineering, B.S.Abdur Rahman Crescent Institute of Science and Technology, Chennai, 600048, Tamil Nadu, India

3Department of Biomedical Engineering, Sri Ramakrishna Engineering College, Coimbatore, Tamil Nadu, India

*Corresponding Author

Email: [email protected]

Received Date:09 November 2022, Accepted Date:23 November 2022, Published Date:31 December 2022

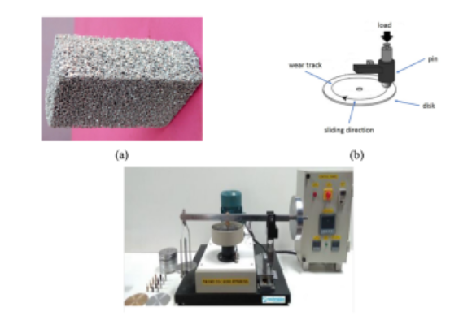

Objectives: This study deals with the optimization of wear properties of Al 6101-alloy foam treated with different temperature zones such as Untreated (UT), Heat Treated (HT), Cryogenic Treated (CT), and Cryogenic Heat Treated (CHT), respectively. The results of this study concerning confirmation tests enable us to validate the proposed optimization findings for the coefficient of friction and specific wear. Methods: The Al 6101 foam samples used in this study are exposed to different heat and cryogenic treatments as well as wear tests using the pin-on-disk apparatus setup with the Taguchi optimization technique. The wear parameters are enhanced further using the Analysis of variance (ANOVA) technique, and this model is processed using the MINITAB software. The Al 6101 foam samples are evaluated using important wear testing parameters like Heat Zone, Load (N), Speed (rpm), and Sliding Distance (m), as well as the output parameters such as coefficient of friction and specific wear (mm3/Nm). Findings: The optimum combination of the coefficient of friction and specific wear, according to the graphic and analytical results of Taguchi’s optimization, is with 40 N load, 400 rpm speed, and 1500 m distance for a cryogenic zone and 40 N load, 400 rpm speed, and 2000 m distance for a cryogenic heat zone, respectively. The interaction of sliding distance, load, and speed, which has probabilities of 17.42, 8.95, and 7.74, respectively, is followed by the coefficient of friction, which has a greater probability percentage of 48.01 for the heat zone. The ANOVA for the specific wear has a higher probability percentage of 48.82 for the load and is followed by the interaction of heat zone, sliding distance, and speed, which have probabilities of 37.59, 6.02, and 2.85, respectively. Novelty: Considering Al 6101 foam, which is mostly a nonferrous material, this experiment once again confirmed that novel cryogenic treatment has a noteworthy improvement in coefficient of friction and specificwear. Additionally, Taguchi’s optimization and ANOVA analysis proved that the Al 6101 closed-cell foam specimen in the CHT zone exhibited optimal results when compared with other heat zones. The results confirmed that the CHT processing improves the wear resistance of the Al 6101 closed-cell foam effectively when examined with other different heat zones.

Keywords: Al 6101 ClosedCell Foam; Cryogenic Treatment; Taguchi Technique; Coefficient Of Friction; Specific Wear; Wear Graph; Surface Morphology; L16 Orthogonal Array; ANOVA

© 2022 Syed et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.