Indian Journal of Science and Technology

DOI: 10.17485/IJST/v17i11.2445

Year: 2024, Volume: 17, Issue: 11, Pages: 1036-1042

Original Article

Doulat Maruti Nangare1*, Sachin Jagonda Patil2, Ganesh Sampatrao Patil1, Amar Appasaheb Dum1, Prashant Pandurang Patil1

1Department of Technology, Shivaji University, Kolhapur, 416004, Maharashtra, India

2Shivohm membrane systems, Kabnur, Ichalkaranji, 416116, Maharashtra, India

*Corresponding Author

Email: [email protected]

Received Date:26 September 2023, Accepted Date:06 February 2024, Published Date:29 February 2024

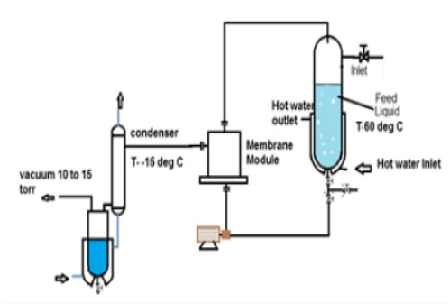

Objective: To compare energy consumption in pervaporation with conventional molecular sieve adsorption process for production of unhydrous ethanol using commercial pervaporation membrane P64 PEPSI C4064.1C. Method/Analysis: Experimental pervaporation system setup with commercial pervaporation membrane P64 PEPSI C4064.1C is used for separation of ethanol water mixture (95% (v/v) ethanol) at vacuum 10-15 torr. For analysis Karl Fischer titration method is used. Based on experimental results electrical as well as thermal energy consumption for 100 KLPD capacity pilot plant is calculated and compared with conventional molecular sieve adsorption process. Findings: Comparison for commercial membrane P64 PEPSI C4064.1C with reported data shows that separation factor as well as total flux related to separation factor is consistent with other hydrophilic membranes. The energy consumption for pervaporation process includes the external heating and cooling required for the feed and permeate streams, as well as the electrical power associated with pumps for re-circulating feed and maintaining vacuum. To separate 100 KLPD ethanol mixture with 95 vol % ethanol by pervaporation process, 10500 kg steam is required whereas 50500 kg steam is required for separation by adsorption process. Total electrical energy for pervaporation process is 76 Kw as compared to 270 kw required for adsorption process. Novelty: This study demonstrated that Electrical energy required for pervaporation process is almost 72 % less than molecular sieve adsorption process. There is no extra energy requirement for External additive addition and separation/sieve regeneration. Based on these results a pervaporation based separation process plant with low energy consumption can be designed for separation of ethanol water mixture.

Keywords: Pervaporation, Energy, Membrane, Molecular sieve, Azeotrope

© 2024 Nangare et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.