Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 4, Pages: 310-318

Original Article

Siddesh Matti1*, B P Shivakumar1, S Shashidhar2, Madeva Nagaral3

1Department of Mechanical Engineering, JSS Academy of Technical Education, Bangalore, Karnataka, India. Tel.: +91 7259249015

2Department of Mechanical Engineering, UVCE, Bangalore, Karnataka, India

3Aircraft Research and Design Centre, HAL, Bangalore, Karnataka, India

*Corresponding Author

Tel: +91 7259249015

Email: [email protected]

Received Date:18 November 2020, Accepted Date:20 January 2021, Published Date:02 February 2021

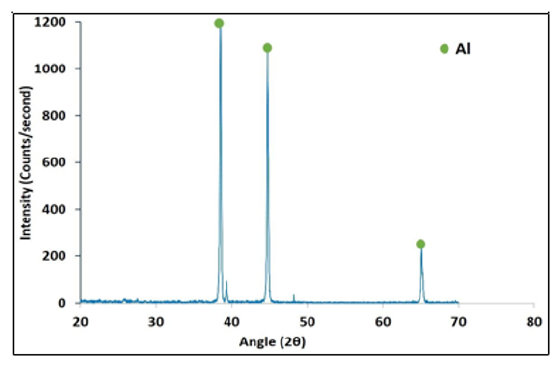

Objective: To synthesize and evaluation of wear behavior of mica. The effect of mica, fly ash and red mud particles reinforced Al7075 alloy composites. Method: The hybrid composites were prepared with constant 1 wt. % of red mud particles and varying weight percentages of mica (2, 4 and 6 wt. %) and fly ash (1, 3 and 5 wt. %) particles in Al7075 alloy by stir casting method. Findings: The synthesized multiple particles reinforced Al7075 alloy hybrid composites were subjected to microstructural studies and wear properties testing. Microstructural characterizations of obtained samples were carried out by scanning electron microscopy and XRD patterns. The mica, fly ash and red mud particles were evenly distributed and presences of these particles were confirmed by the XRD patterns. Novelty /Improvement: Al7075 alloy with red mud, fly ash and mica particles reinforced hybrid composites were exhibited the superior wear resistance. Various wear mechanisms were observed in the Al7075 alloy with mica, fly ash and red mud composites using SEM.

Keywords: Al7075 Alloy; Mica; Fly Ash; Red Mud; Wear; Worn Morphology

© 2021 Matti et al.This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.