Indian Journal of Science and Technology

Year: 2023, Volume: 16, Issue: 17, Pages: 1260-1267

Original Article

P Balaramesh1*, S Jayalakshmi2, V Anitha3, Absara Fdo4, P Venkatesh5

1Associate Professor, Department of Chemistry, R.M.K. Engineering College, Chennai, 601206, Tamil Nadu, India

2Assistant Professor, Department of Chemistry, VISTAS, Chennai, 600 117, Tamil Nadu, India

3Assistant Professor, Department of Chemistry, Vellammal Engineering College, Chennai, 600 066, Tamil Nadu, India

4Research Scholar, Department of Chemistry, Pachaiyappa’s College, Chennai, 600 030, Tamil Nadu, India

5Associate Professor, Department of Chemistry, Pachaiyappa’s College, Chennai, 600 030, Tamil Nadu, India

*Corresponding Author

Email: [email protected]

Received Date:13 January 2023, Accepted Date:10 April 2023, Published Date:28 April 2023

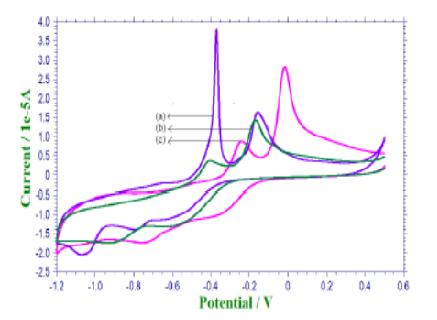

Objective: The coordination and electrochemistry-related effects and uses of piperidine dithiocarbamate (pipdtc) and piperazine dithiocarbamate (pzdtc) are the main topics of this article. Method: An environment friendly electroless bath was created using a very small amount of biodegradable methanesulphonic bronsted acid, Glyoxylic acid as a reducing agent, Xylitol as a non-toxic natural polyhydroxylic complexing agent and potassium hydroxide as pH modifier. Compact and finer deposits were obtained at pH 13.0 and 45◦C with an addition of 1 ppm of pipdtc and pzdtc in an optimized bath. Findings: The inhibiting effect of pipdtc and pzdtc additives depends on deposit properties, throwing power, thickness uniformity, surface tension and grain structure management. Novelty: In this electroless copper plating method, pipdtc and pzdtc improved the physical properties and produced quality deposits. Gravimetric and weight gain calculations were used to determine the physical parameters. AFM experiments were used to describe the surface morphologies of copper deposits. By using X-ray diffractogram (XRD) analysis, the copper deposits’ crystallite sizes were quantified, and cyclic voltammetry analysis was used to assess their quality. Keywords: Glyoxylic acid; Piperazine dithiocarbamate; Piperidine dithiocarbamate; Surface morphology; Xylitol

© 2023 Balaramesh et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.