Indian Journal of Science and Technology

DOI: 10.17485/IJST/v16i47.2637

Year: 2023, Volume: 16, Issue: 47, Pages: 4469-4480

Original Article

L Daniel Devaraj1*, V Srinivasan2

1Reseach Scholar, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, 608 002, Tamil Nadu, India

2Associate Professor, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, 608 002, Tamil Nadu, India

*Corresponding Author

Email: [email protected]

Received Date:17 October 2023, Accepted Date:23 October 2023, Published Date:20 December 2023

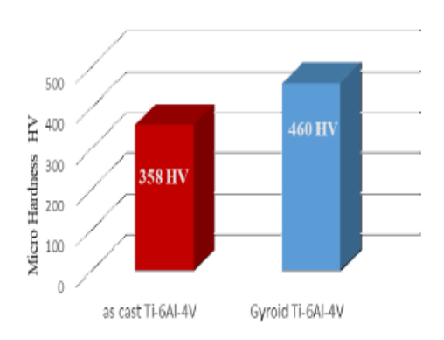

Objectives: To investigate the Micro Hardness, Micro structures and wear characteristics of the TPMS (Triply Periodic Minimal Surface) Gyroid structures with optimized porosity percentage for Bio medical application. Methods: Micro Hardness tester is used to find the micro hardness of the as cast Ti-6AL-4V and Gyroid Ti-6Al-4V Sample. Wear tests using pin-on-disc tribometer was used to assess the Gyroid Ti-6Al-4V wear samples for various loads and sliding velocity. The wear test parameters were test as load of 10, 30 & 50 N, with the sliding velocity of 0.5, 1.0 7 1.5 m/s. Atomic force microscope has been used for finding the surface roughness of the as cast and Gyroid Ti-6Al-4V samples before and after wear test. Findings: According to the test results. It is found that Gyroid Ti-6Al-4V samples posses more wear resistance than as cast Ti-6Al-4V. The micro hardness test results depicted clearly that, the Gyroid Ti-6Al-4V alloy posses’ micro hardness of 408 HV in comparison with as cast Ti-6Al-4V alloys’ hardness of 358 HV. The morphological characteristics of the worn-out samples were investigated using scanning electron microscope. At higher sliding conditions occurrence of large friction events lead to higher wear rates and the periodic localised fracture of transfer layer. At low sliding conditions, the Gyroid Ti-6Al-4V samples experienced ploughing, peeling off, plastic deformation types of wear mechanism. Novelty: The wear modes were categorised by the Fuzzy C-means algorithm, and a novel PNN tool in MATLAB created a wear map mechanism suitable for the Gyroid Ti alloy. The research conducted in this paper demonstrates a novel methodology for investigating wear mapping using a Probabilistic Neural Network on wear samples with a Gyroid lattice structure.

Keywords: TPMS, Lattice/porous structure, Micro Hardness, Wear Characteristics, Ti-6Al-4V

© 2023 Devaraj & Srinivasan. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.