Indian Journal of Science and Technology

DOI: 10.17485/IJST/v17i13.2626

Year: 2024, Volume: 17, Issue: 13, Pages: 1252-1262

Original Article

Yamako Soungalo Soulama1*, Frédéric Bationo2, Fidèle Wend-Bénédo Tapsoba2

1Department of Rural Engineering and Agricultural Machinery, Research Team on Agricultural Mechanization and Process Engineering [ERMAP/UL], Graduate School of Agronomy, University of Lomé [ESA/UL], Togo

2Institute for Research in Applied Sciences and Technologies of the National Center for Scientific and Technological Research [IRSAT/CNRST], Burkina Faso

*Corresponding Author

Email: [email protected]

Received Date:21 October 2023, Accepted Date:28 February 2024, Published Date:21 March 2024

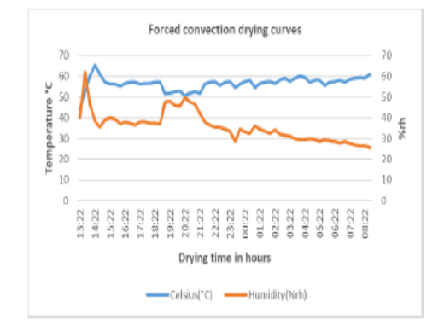

Objective: Evaluating the performance of the ATESTA [Solar Energy and Appropriate Technology Workshop] forced convection dryer, developed at the Albert Schweitzer Ecological Center of Burkina [CEAS Burkina], on the drying of pineapple slices in Togo. Method: For this purpose, two ATESTA dryers were setup in a company in Lomé, Togo, one operating in forced convection and the other, the witness, in natural convection mode. Drying tests of pineapple slices were carried out with these two dryers. Data were collected on water loss, organoleptic parameters and energy consumption during the drying process Findings: The results showed that the water loss rate increased by 11.4% as well as the first choice dry matter content by 36% and an energy saving of 21% percent of natural convection to forced convection. This performance of the ATESTA forced convection dryer increases the economic profit of USD [United States Dollar] 2.68/kg or USD 45.52/drying cycle and USD 2678.40/t of dried pineapples. The results of microbiological analyses revealed that the total flora [1.2.102 CFU/g] [Colony-Forming Unit per gram] yeast and mold [6.4.101 CFU/g] content of pineapple slices dried by the ATESTA forced convection dryer were in line with the limit values of the Directive 2000/13/EC [European Parliament and the Council]. Novelty: Performance tests on the forced convection dryer have made a more efficient dryer available to pineapple processors. Forced convection can also be adapted to existing dryers.

Keywords: Performance, ATESTA dryer, Togo, Forced convection, Dried prineapple

© 2024 Soulama et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.