Indian Journal of Science and Technology

DOI: 10.17485/IJST/v15i43.1830

Year: 2022, Volume: 15, Issue: 43, Pages: 2342-2350

Original Article

D Jayaprakash1*, K Niranjan2, B Vinod3

1Research Scholar, Department of Manufacturing Engineering, Annamalai University, Chidambaram, 608002, Tamil Nadu, India

2Assistant Professor, Department of Manufacturing Engineering, Annamalai University, Chidambaram, 608002, Tamil Nadu, India

3Associate Professor, Department of Mechanical Engineering, Siddharth Institute of Engineering & Technology, Puttur, 517583, Andra Pradesh, India

*Corresponding Author

Email: [email protected]

Received Date:11 September 2022, Accepted Date:10 October 2022, Published Date:18 November 2022

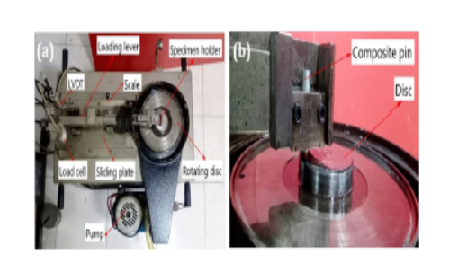

Objectives: To investigate the tribological behaviour of aluminium hybrid composites. Aluminium alloy (LM 25) is utilised in the aerospace and defence industries. Its wear properties are further improved to increase the lifespan of the components used in these sectors. Due to their ability to resist wear, graphite and silicon carbide are often used to manufacture machine tools. The objective is to identify the wear parameters of the LM 25 alloy. It was examined after stir-cased and strengthened with silicon carbide and graphite in various weight ratios. Methods: The dry sliding wear behaviour for aluminium alloys containing 2, 4, and 6 wt.% silicon carbide and a fixed 2 wt.% graphite is investigated using stir-casting composites. These process parameters included loads of 15, 30, and 45 N, sliding speeds of 0.55, 1.10, and 1.65 m/s, and sliding distances of 333, 666, and 999 m. Findings: According to the test results, the overall wear loss of SiC-reinforced hybrid composites was less compared to both unreinforced alloys and Al/Gr composites. The tribological behaviour of a composite consisting of 4% SiC and 2% Gr was significantly improved compared to the base alloy. Novelty: The novelty of this study is to induce a brake disc made of an Al alloy with wear-resistant SiC/Gr particle-reinforced aluminium composites committed to its surface. The role of tribology in determining material behaviour is shown to be important in controlling material removal.

Keywords: LM25Al Alloy; Silicon carbide; Graphite; Double stircasing; Wear resistance; Worn surface morphology

© 2022 Jayaprakash et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.