Indian Journal of Science and Technology

Year: 2020, Volume: 13, Issue: 26, Pages: 2657-2667

Review Article

N Manigandan1*, V Ponmalar2

1Research Scholar, Department of Civil Engineering, Anna University, Chennai, India. Tel.: +91-994-292-6726

2Associate Professor, Division of Structural Engineering, Department of Civil Engineering, Anna University, Chennai, India

*Corresponding author

Tel.: +91-994-292-6726

Email: [email protected]

Received Date:07 May 2020, Accepted Date:15 July 2020, Published Date:30 July 2020

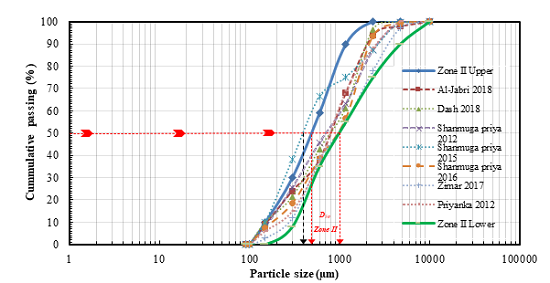

Background/Objective: To review on the river sand supplants particularly Manufactured sand (Msand) and Ferrochrome slag (FeCr slag) aggregate in concrete and mortar matrix. Methods: A study on FeCr slag as sand is skimpy and countable; so here they clustered together and discussed for its performance. Msand by its shape, texture, physiochemical characters, strength parameters and durability is much similar to river sand in a concrete matrix. FeCr slag shape and texture is almost similar but porous in nature and ingredients like MgO and Cr2O3can cause an effect on concrete. Msand based on various grades and mechanical strength is analysed. Findings: Msand strength behaviour is discussed in detail with reference to other authors which clearly states that Msand is ideal for fine aggregate replacement. Industrial waste FeCr slag is replaced instead of sand, which also behaves well until 40% to 50% replacement of sand at later ages of strength. Compressive strength, splitting tensile strength and flexural strength of these two materials are graphically depicted from a literature surveys of recent researches. Novelty: This study provides robust information about strength performance of Msand and FeCr slag with varying percentage ranges from 10% to 60% by weight.

Keywords: Msand; ferrochrome slag; strength; compressive; splitting; flexural; river sand

© 2020 Manigandan, Ponmalar. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.