Indian Journal of Science and Technology

Year: 2023, Volume: 16, Issue: 36, Pages: 2973-2981

Original Article

J Jesumanen1*, M Chandrasekaran2, P Babu Aurtherson1

1Department of Mechanical Engineering, DMI Engineering College, Aralvaimozhi, TamilNadu, India

2Department of Mechanical Engineering, Vels Institute of science, technology and advanced studies (VISTAS), Pallavaram, Chennai, 600117, Tamil Nadu, India

*Corresponding Author

Email: [email protected]

Received Date:04 March 2023, Accepted Date:17 June 2023, Published Date:27 September 2023

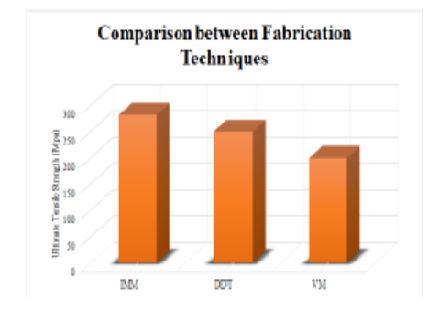

Background: Magnesium (Mg) is regarded as the most accessible element in the Earth crust and possess low structural density with increased specific strength. Selective Laser Melting (SLM) is considered as a more dependable method of creating Mg-based products. In SLM, build orientation affects mechanical properties, causing ductility to increase and tensile strength to decrease. Objectives: To improve the mechanical properties and increase the tensile strength and yield strength China low activation martensitic (CLAM) steels different yttrium (Y) contents are utilized. Methods: A fabrication of reinforced composites namely Al-Zn or Fly Ash or SiC is carried out by Stir Casting Route using Vortex Method. Powder metallurgy route is employed for preparing Al-Zr relied metal matrix composites. Findings: CLAM has good tensile strength and yield strength, when compared to the other alloys in mechanical properties. A comprehensive analysis is carried out about the impacts of different Y additions over the Mg based alloys and the resulting texture, microstructure and tensile properties beneath different processes are analysed in this paper. Novelty: CLAM is utilized to enhance the tensile strength and the analogization amid the alloy proportions which shows that the Y-CLAM possesses better tensile and yield strength of 550 Mpa compared to the existing methods.

Keywords: Magnesium (Mg); Yttrium (Y); Tensile Strength and Yield Strength (YS); CLAM; Mechanical properties

© 2023 Jesumanen et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.