Indian Journal of Science and Technology

Year: 2020, Volume: 13, Issue: 25, Pages: 2582-2592

Original Article

Lucky1*, Harish Arya2

1Department of Mechanical Engineering, SLIET Longowal, 148106, Punjab, Tel.: +919417424879 2Department of Mechanical Engineering, SLIET Longowal, 148106, Punjab

*Corresponding Author

Tel:+919417424879

Email: [email protected]

Received Date:06 June 2020, Accepted Date:30 June 2020, Published Date:21 July 2020

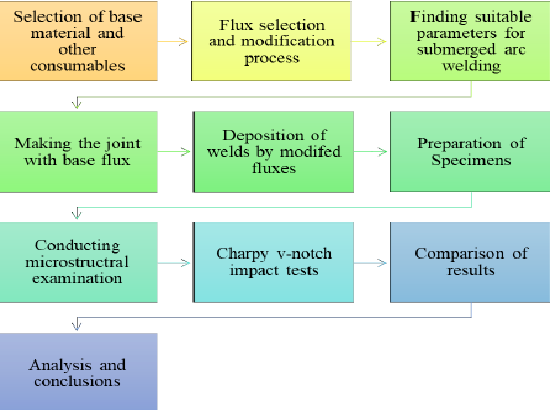

Objectives: To analyse the effects of rutile (TiO2) and Alumina (Al2O3) on impact toughness properties of Submerged arc welded joints for low temperature applications. Methods: Al2O3 and TiO2 have been added to F7AZ/PZ-EL8 Submerged arc welding (SAW) flux in varying quantities and the base material used for joining is low carbon structural steel having E350 grade. To verify the effect of these elements by flux modification, the Charpy V-Notch impact tests, scanning electron microscope (SEM) fractography and visible light microscopy (VLM) have been conducted. Findings: Charpy V-Notch impact testing and analysis have shown that there is considerable improvement in the impact properties of welds with the addition of 20% TiO2 and 20% Al2O3 in the 80% of flux as separate constituents i.e., when these elements have been added in the flux in separate form or two new modified fluxes were prepared, where one is doped with alumina and other is with rutile. Fractography of welds with addition of 20% alumina in 80% F7AZ/PZ-EL8 SAW fluxes are having best impact properties at lower temperature and addition of 20% rutile also as almost effective as alumina in flux. consequently, mode of failure is ductile fracture with dimples as a result of good amount of acicular ferrite microstructure. Novelty: Analysis of previous studies implicated that there is lack of significant studies in the low temperature impact properties of low carbon steel submerged arc welds. Present study shows that the significant improvement in the toughness properties of welds at lower temperature of -40◦C can be achieved through flux modification, it would ensure the application of Low carbon steel structures at lower working temperature. The applications may be pressure vessels, ships or containers.

Keywords: Submerged arc welding (SAW); low temperature impact toughness; flux modification; low carbon steels

© 2020 Lucky, Arya.This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.