Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 7, Pages: 583-591

Original Article

M Anil Kumar1*, V Srinivasan2, P Ramamurthy Raju3

1Research Scholar, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, 608 002, Tamil Nadu, India

2Associate Professor, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, 608 002, Tamil Nadu, India

3Professor, SRKR Engineering College, Bhimavaram, Andhra Pradesh, India

*Corresponding Author

Email: [email protected]

Received Date:08 November 2023, Accepted Date:13 January 2024, Published Date:08 February 2024

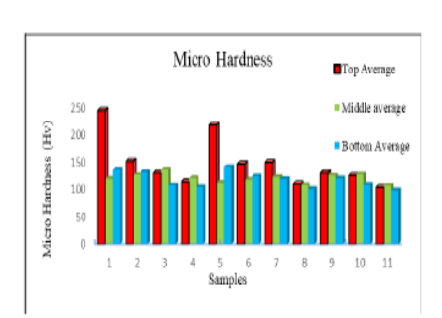

Objectives: The aim of this study is to examine the mechanical and microstructural properties of functionally graded material (FGM) composites based on magnesium (Mg). Magnesium alloys are commonly employed in the development of biomaterials for implant applications owing to their favorable corrosion properties. The research objective is to study the microstructural and mechanical properties and produce Zn/Mo reinforced functionally graded magnesium composites using the centrifugal casting. Methods: A triple layered cylindrical shaped Mg based functionally graded material (FGM) was fabricated through a centrifugal process from (Mg (80%) +Zn (10%) + Mo (10%) alloy. The developed FGMs have been analyzed for their mechanical and microstructural characteristics. The microstructure was analyzed via the OM AND SEM microscope. It is identified that denser particle molybdenum (Mo) have influenced the mechanical and microstructural characteristics. Findings: Results recommend that, all the three layered testing’s, Mg (80%) +Zn (10%) + Mo (10%) composite exhibited favorable mechanical and microstructural properties. It is identified that denser particle of Mo which is influenced the microstructural characteristics. The alteration in micro hardness in the direction of centrifugal force is observed, and it is perceived that top surface has higher hardness as compared to the middle and bottom region. The flexural strength of top surface sample is 254 MPa, which is 10% greater than middle surface sample and 12.36% greater than bottom surface sample. Compressive strength of 385 MPa, surpassing the middle surface sample by 17.11% and the bottom surface sample by 19.36%. Novelty: In this study, a novel three-layered centrifugal casting technique was devised. Owing to its rapid degradability, the anticipated duration of the implants within the human body is significantly shorter in comparison to alternative biomaterials such as Titanium and Stainless steel. Furthermore, the findings from the conducted tests strongly advocate for the utilization of this technique in biomedical implantations.

Keywords: Functionally graded material (FGM), Centrifugal casting, Mechanical properties, Microstructural behavior and bioimplants

© 2024 Kumar et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.