Indian Journal of Science and Technology

DOI: 10.17485/IJST/v16i40.1882

Year: 2023, Volume: 16, Issue: 40, Pages: 3443-3452

Original Article

L Daniel Devaraj1*, V Srinivasan2, S Selvabharathi3

1Reseach Scholar, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, 608 002, Tamil Nadu, India

2Associate Professor, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, 608 002, Tamil Nadu, India

3M. E Student, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, 608 002, Tamil Nadu, India

*Corresponding Author

Email: [email protected]

Received Date:27 July 2023, Accepted Date:11 September 2023, Published Date:25 October 2023

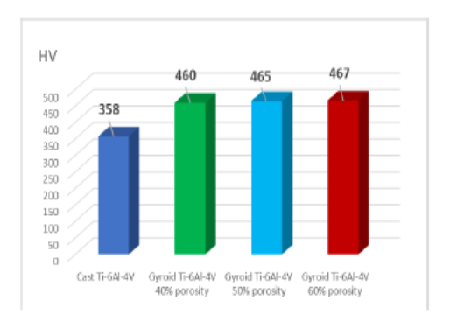

Objectives: To evaluate the tribological and corrosive characteristics of an additively printed gyroid Ti-6Al-4V for Bio medical implant application. Methods: Direct Metal Laser Sintering with regulated input process parameters were used to print the samples. Corrosion investigations have been completely investigated using Potentiodynamic polarization under simulated body fluid conditions. The wear parameters for the samples were maintained with normal load ranging from 10 to 50 N, with sliding velocity ranging from 0.5 to 1.5 m/s for a sliding distance of 1000 m. The further study investigates the impact of load and velocity on the coefficient of friction (COF) and wear rate of the Gyroid samples. Findings: According to the results obtained, the material with the highest resistance to corrosion is exhibited by gyroid lattice Ti-6Al-4V that has a porosity of 60%. These samples exhibited by a worn-out rate of 2 x 10-11 m3/m and 5.3 x 10-11 m3/m for the normal load of 10 N and 50 N respectively. Minimum wear rate of 3.3 x 10-11 m3/m was obtained for a sliding velocity of 0.5 m/s, where a maximum wear rate was obtained at 1.5 m/s of 3.7 x 10-11 m3/m. Sample C has better tribological properties and is shown good wear resistance, when compared to sample A & B, which is attributed to the highest micro hardness of sample C of 467 HV. Novelty: The work presented in this study exhibits a unique approach by fabricating a gyroid lattice structure with varying levels of porosity. The limited availability of literature on tribological and corrosion issues necessitates the identification of a unique research need. An investigation of the effect of wear mechanisms on the tribological features of Gyroid Ti-6Al-4V is considered to be a unique research attempt.

Keywords: Ti6Al4V, Direct Metal Laser Sintering technology, Microhardness, Potentiodynamic Polarization, Tribology, Biomedical implants

© 2023 Devaraj et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.