Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 37, Pages: 2850-2859

Original Article

Mohamed Sayed Alashhab1,2*, Ehab A Mlybari1

1College of Engineering and Islamic architecture, Umm Al-Qura University, Makkah, Saudi Arabia

2Faculty of Engineering, Ain-Shams University, Cairo, Egypt

*Corresponding Author

Email: [email protected]

Received Date:18 May 2021, Accepted Date:19 July 2021, Published Date:03 November 2021

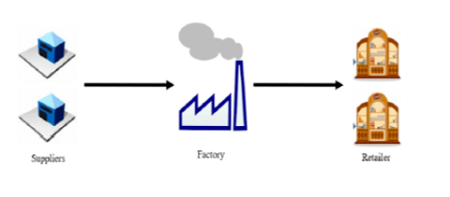

Objectives: To develop a multi-item, multi-product, and multi-period mathematical model that optimizes supply, production, distribution, and inventory planning for a supply chain network. Methods: Mixed Integer Linear Programming has been used to formulate the proposed model, while Excel and Evolver solvers have been used to solve problems regarding supply chain network (consisting of two suppliers and two retailers) for profit maximization. Findings: The analysis showed that the developed model has the ability to efficiently and effectively solve real-life problems of the multi-item, multi-product, and multiperiod supply chain. Novelty: The model considered multi-item, multi-product, and multi-period. In addition, it considers initial, final, and intermittent inventory in multi-periods. The model is solved using both Excel and Evolver solvers. The model assists organizations involved in the supply chain to design and plan their network efficiently.

Keywords: Supply chain; multi-item; multi-products; multi-periods; MILP;Excel; Evolver Solver

© 2021 Alashhab & Mlybari. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.