Indian Journal of Science and Technology

Year: 2020, Volume: 13, Issue: 26, Pages: 2609-2624

Original Article

J Stephen Leon1*, G Bharathiraja1, V Jayakumar2

1Department of Mechanical Engineering, Saveetha School of Engineering, Saveetha Institute

of Medical and Technical Sciences, Chennai, Tamilnadu

2Department of Mechanical Engineering, Amrita School of Engineering, Chennai, Amrita

Vishwa Vidyapeetham, Tamilnadu

*Corresponding Author

Email: [email protected]

Received Date:09 June 2020, Accepted Date:08 July 2020, Published Date:27 July 2020

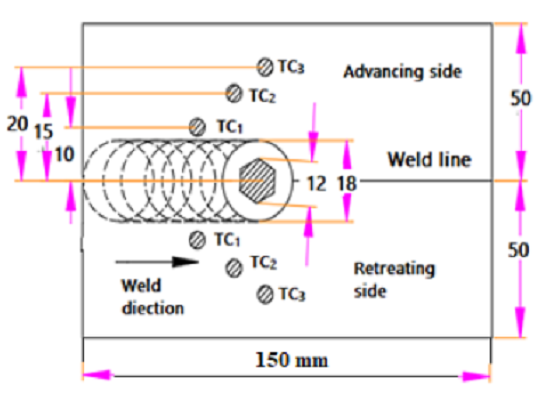

Background/Objectives: In friction stir welding, tools with flat faced pin delivers better weld quality than cylindrical pin. In flat faced pin, improper selection of process parameters often results premature tool failure. Being easily controllable process parameters, proper selection of tool rotation speed with respect to the tool advancing speed not only avoids unwanted weld defects but also enhances tool life. Methods: An integrated experimental and numerical comparative study is made between air and water cooled processes to understand the effects of heat dissipation through the boundaries on temperature distribution. Findings: Optimum range of Pseudo Heat Index (PHI) is achieved by comparing the obtained temperature distribution with material softening temperature. Optimum range of weld speed with respect to the tool rotation speed is derived through the optimum Pseudo heat index. Experimental study on the joint strength validates the proposed optimal process parameter ranges. Novelty : This study outlines a novel approach to develop an optimum process window based on PHI for air and water cooled friction stir welding using tools with flat faced pin.

Keywords: Optimization; friction stir welding; thermomechanical; pseudo heat index; experimentation; numerical modeling

© 2020 Stephen Leon, Bharathiraja, Jayakumar.This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.