Indian Journal of Science and Technology

DOI: 10.17485/IJST/v16i42.2168

Year: 2023, Volume: 16, Issue: 42, Pages: 3814-3820

Original Article

P Praveen Kumar1*, K G Subramanya1, S Manjunatha1

1Assistant Professor, Department of Civil Engineering, Govt SKSJT Institute, Bangalore, 560001, Karnataka, India

*Corresponding Author

Email: [email protected]

Received Date:25 August 2023, Accepted Date:22 September 2023, Published Date:13 November 2023

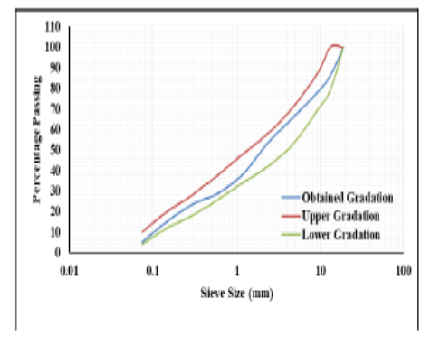

Objectives: To find the suitability of Bituminous Concrete (BC) Grade-II mix as a pavement surface course layer using conventional bitumen and modified bitumen. Methods: The present research is carried out by conducting the Marshall stability test on the bituminous mixes by using Crumb Rubber Modified Bitumen (CRMB), also known as modified bitumen, on the Bituminous Concrete Grade-I (Gr-I) and Bituminous Concrete Grade-II (Gr-II) mixes. The gradation for the bituminous mixes is achieved by the trial and error method to obtain the suitable Job Mix Formula (JMF). Samples were prepared for varying percentages of conventional and crumb rubber modified bitumen, ranging from 5.0% to 6.25% by weight of bitumen. The Marshall parameters are analysed for different percentages of bitumen and modified bitumen. Findings: The Optimum Binder Content (OBC) for the crumb rubber modified bituminous mixes is 0.3% lower than the conventional bituminous mixes, and the mix prepared with modified bitumen showed a higher stability value of 20.2%, which greatly helps in increasing the service life of the pavement. In addition, the modified bitumen exhibited less flow than the conventional bituminous mix, indicating that it was less susceptible to temperature and enhancing the pavement’s durability. Based on the research findings, it is more suitable to use BC Gr-II as a surface course layer on all the important highways than BC Gr-I. The research findings help to choose the grade of bituminous concrete to be used in the Indian context. Novelty: The novelty of the study lies in its approach to using waste materials in pavement construction, reducing the use of natural resources, reducing the cost of construction, enhancing the durability of pavement surfaces, and simultaneously mitigating the waste disposal problem.

Keywords: Bituminous Concrete, Marshall Stability, Crumb Rubber Modified Bitumen, Service Life, Waste Disposal

© 2023 Kumar et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.