Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 24, Pages: 2081-2087

Original Article

Mandeep Singh1,*, Dilbag Singh2, A S Shahi3

Received Date:27 January 2021, Accepted Date:30 March 2021, Published Date:19 July 2021

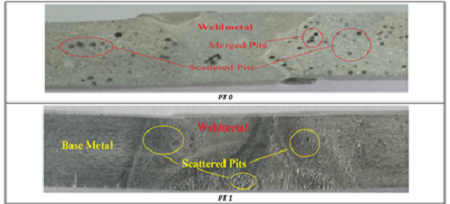

Objectives: The present experimental work investigates the effect of post weld heat treatments on the pitting, impact toughness and metallurgical properties of gas tungsten arc welded martensitic stainless steel joints. Methods/Statistical analysis: Martensitic stainless steel (AISI410 SS) cold rolled plates used as a base materials and welded using GTAW process with two filler materials (ER 304LSS and ER 410 SS for root pass and cover passes respectively). Three heat treatments namely annealing, quenching and plasma nitriding were given to the specimens. After the heat treatments the specimens were subjected to pitting corrosion test, impact toughness test, microhardness testing and microstructural examination. Findings: Pitting corrosion results under different heat treatments of the welds showed that the post weld heat treatment induces the significant variations in the pitting resistance. The maximum pitting resistance (minimum mass loss of 0.5108mg) was possessed by the weld with plasma nitriding treatment. The maximum energy absorption capacity of the welds of 62 Joules was obtained in the annealing treatment. The average microhardness values of 474VHN, 372 VHN, 492VHN and 559VHN was obtained in as welded condition, under annealing treatment, under quenching treatment and under plasma nitriding treatment respectively of the welded joints. Based on the micro-structural studies of the welded joint in as received and post weld heat treated conditions, the significant microstructural changes were observed in weld metal zones. Novelty/Applications: The present experimental study can beneficially be adopted for welding of martensitic stainless steel (AISI 410 SS) as it suggests the processing conditions to forecast the adequate pitting resistance, impact toughness and microhardness behaviour in similar service conditions.

Keywords

Pitting corrosion, impact toughness, post weld heat treatments, microhardness, microstructure, GTAW

© 2021 Singh et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.