Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 31, Pages: 2535-2541

Original Article

Logesh Kumar M1, Baskar Prabu2, Annadurai Shalini2*

1Associate Professor, Department of Civil Engineering, Sona College of Technology, 636005,

India

2Assistant Professor, Department of Civil Engineering, Sona College of Technology, 636005,

India

*Corresponding Author

Email: [email protected]

Received Date:17 May 2021, Accepted Date:20 August 2021, Published Date:21 September 2021

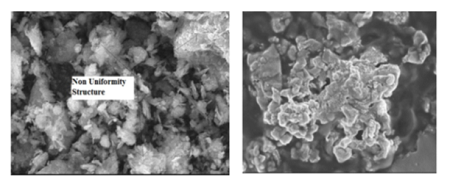

Objective: To investigate the physical and strength properties of mortar using locally available mineral admixture. Methodology: The compressive strength of the mortar at different temperatures was found. Setting time, consistency, and porosity were also studied by blending natural kaolinite and metakaolinite (MK) with cement in different proportions. An experimental work was carried out using control mix and adding kaolinite from 5% to 20% in ordinary Portland cement (OPC) at 5% equal intervals. Findings: The test results revealed that the use of natural admixtures such as Natural kaolinite (NK) and MK in OPC enhances the performance of the binder in mortar. The compressive strength enhancement of natural kaolinite cement–blended binder was comparatively lower than that of control mortar for all percentages whereas the mortar added to MK had increased strength. MK mortar with a 15% mix proportion was the optimum one to yield maximum compressive strength. Novelty: The present research work is focused on the partial replacement of metakaoline with temperature variant and the percentage of dosage used as a double variant parameter.

Keywords: Natural kaolinite; Metakaolinite; Calcination; Apparent porosity; Compressive strength

© 2021 Logesh Kumar M et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.