Indian Journal of Science and Technology

Year: 2020, Volume: 13, Issue: 37, Pages: 3850-3870

Original Article

Pratiksha Saxena1, Chaman Singh2, Kamna Sharma1*

1Department of Mathematics, Gautam Buddha University, Greater Noida, Uttar Pradesh,India

2Department of Mathematics, Acharya Narendra Dev College, University of Delhi, Delhi

*Corresponding Author

Email: [email protected]

Received Date:19 May 2020, Accepted Date:15 September 2020, Published Date:13 October 2020

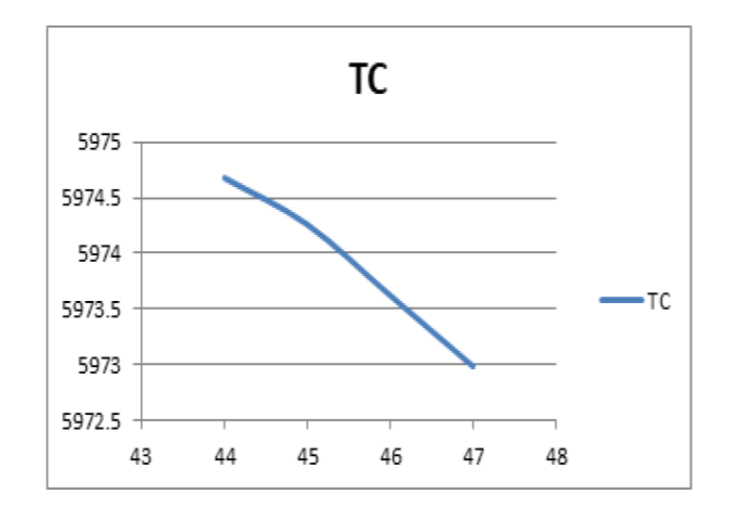

Background/Objectives: To trim down the recycling cost of any manufactured goods with the help of green design and product stewardship. Methods/Statistical analysis: For the planned EPQ (economic production quantity model) model, all costs are calculated to find total cost and this total cost is optimized with the help of the Hessian matrix. Sensitivity analysis is also carried w.r.t. different parameters, to illustrate the impact of these parameters on the proposed model. The convexity of the total cost function is also checked with the help of mathematical software Mathematica 9.0. Findings: Major finding of the proposed model are as follows: (i) Increase in the number of recycles results in the reduction of the total cost. (ii) Product stewardship parameter has a negative effect on total cost as the PS increases from 1 to 4 units, total cost decreases from 5926.00 to 5918.96 units (see Table 9 ) (similar findings can be written for numeric example 1 after correcting it). (iii) Green design costs have a positive effect on total cost, as the green design cost increases from 3 to 6 units, total cost also increases from 5918.49 to 5920.37 units (see Table 10 ). (iv) increase in the number of recycles results in the reduction of the total cost, as the number of recycles increases from 20 to 50 units total cost decreases from 5922.87 to 5919.12 units (see Table 11 ). Novelty/Applications: The Study of the effects of recycling by this green design and product stewardship approach makes the proposed model distinctive from the existing methods. The proposed model applies to eco-friendly manufacturing items with green design and product stewardship.

Keywords: Green design; product stewardship; production model; own warehouse (OW); rented warehouse (RW); shortage; deterioration

© 2020 Saxena et al.This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee).

Subscribe now for latest articles and news.