Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 22, Pages: 1905-1913

Original Article

Madjid Belabbaci 1,*, Zakaria Imine 1, Tewfik Ghomari 1, Bachir Imine 1

1 Laboratory of Aeronautics and propulsive systems in USTO of Oran in Algeria

*Corresponding author email: [email protected]

Received Date:15 January 2021, Accepted Date:13 May 2021, Published Date:02 July 2021

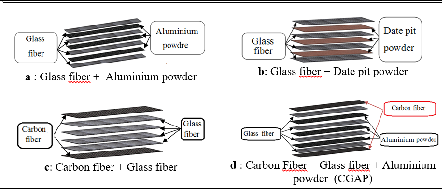

Objective: The aim of this article is to solve the problem of wing spar flexibility of an aluminium drone aircraft. A 200 × 30 [mm × mm] aluminium sample weighing 32 g was collected corresponding to a density of 0.53 g/cm3, a bending load of 0.77 [kN] and a deflection of 45.54 mm. The goal is to increase flexion resistance and lightness. Methods: The following procedure was used to prepare the composite: a mold made up of two glass plates 250 mm long and 50 mm wide, gel-coated to prevent sticking. The mold was placed in a bag using vacuum bag technology by means of a refrigerator compressor. The bag was then heated at 80 °C for seven hours to prepare composites of acceptable quality and viscosity avoiding air bubbles and ensuring desired thickness. The first sample was prepared by inserting aluminium powder between four layers of glass fiber. In the second sample, the inserted layer was replaced by date pit powder. The third sample was prepared by placing four layers of glass fiber and two layers of carbon fiber in the lower layer and the upper layer. It was observed that aluminium powder inclusion resulted in better mechanical properties in comparison to date pit powder. Findings: However, the mechanical characteristics of the third sample were much better than those of the other samples. Based on these observations, the first and third samples were mixed to make the fourth sample in which four layers of glass fiber between each layer were used, placing the aluminium powder plus two layers of carbon fiber in the lower and upper layers with the aim of achieving the desired mechanical properties. The latter sample exhibited high strength and better curvature, high rigidity and corrosion resistance with the possibility of creating structures that are more integrated. These properties make the aluminium powder –carbon fiber based composite suitable for a drone aircraft wing spar. The obtained composite material prepared from glass fiber, aluminium powder, carbon fiber composed of four layers of glass fiber and aluminium powder between each layer and carbon fiber in the bottom layer and top layer exhibited has high strength, better bending, high stiffness and corrosion resistance with the possibility of creating more integrated structures. The prepared sample may outstand aluminium -based aircraft wing spar.

Keywords

Wing spar, bending, composite materials, aluminiumcarbon fiber

© 2021 Belabbaci et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.