Indian Journal of Science and Technology

DOI: 10.17485/IJST/v14i45.1705

Year: 2021, Volume: 14, Issue: 45, Pages: 3346-3353

Original Article

Manjunath Prasad1*, U N Kempaiah2, R Murali Mohan3, Madeva Nagaral4

1Research Scholar, Department of Mechanical Engineering, UVCE, Bangalore 560001

2Professor, Department of Mechanical Engineering, UVCE, Bangalore 560001

3Assistant Professor, Department of Mechanical Engineering, Deputy Manager, Government

Engineering College, Hassan, 573202

4Deputy Manager, Aircraft Research and Design Centre, HAL, Bangalore 560037

*Corresponding Author

Email: [email protected]

Received Date:30 September 2021, Accepted Date:12 December 2021, Published Date:22 December 2021

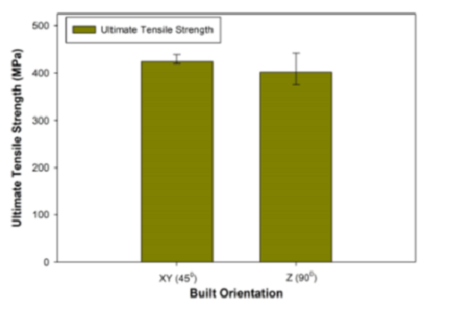

Objective: To evaluate the tensile and compression behaviour of Al-Si10-Mg alloy developed by selective laser melting (SLM) process. Method: Al-Mg10-Si alloy developed by SLM process along XY (45°) and Z (90°) orientations. These prepared samples were subjected to microstructural characterization by SEM and EDS. Mechanical properties like tensile and compression behaviours were evaluated according to ASTM standards. Findings: Microstructural studies revealed the effect of grains on the mechanical behaviour of Al-Mg10-Si alloy built in XY (45°) and Z (90°) orientations. EDS analysis confirmed the presence of Mg and Si elements in the Al matrix. Tensile strength of Al-Mg10-Si alloy built in XY (45°) orientation is 428.6 MPa against 408.3 MPa in Z (90°) orientations developed samples. Further, compression strength of samples developed in XY (45°) orientation is more than that of developed in Z (90°) orientations. Novelty: In the current study Al-Mg10-Si alloy samples were produced by selective laser meting method in XY (45°) and Z (90°) orientations. Very minimal investigations were carried out on Al-Mg10-Si alloy specimens built in XY (45°) orientation. Keywords: AlMg10Si Alloy; Microstructure; Tensile Behaviour; Compression Strength; Build Orientation

© 2021 Prasad et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.