Indian Journal of Science and Technology

DOI: 10.17485/IJST/v14i28.1341

Year: 2021, Volume: 14, Issue: 28, Pages: 2342-2350

Original Article

V A Anjan Babu1,2*, R Saravanan3, M Raviprakash4, Madeva Nagaral5

1Research Scholar, Department of Mechanical Engineering, UVCE, Bangalore, 560001

2Assistant Professor, Department of Mechanical Engineering, East Point College of

Engineering & Technology, Bangalore, 560083

3Associate Professor, Department of Mechanical Engineering, UVCE, Bangalore, 560001

4Associate Professor, Department of Mechanical Engineering, The Oxford College of

Engineering, Bangalore, 560068

5Deputy Manager, Aircraft Research and Design Centre, HAL, Bangalore, 560037

*Corresponding Author

Email: [email protected]

Received Date:20 July 2021, Accepted Date:28 July 2021, Published Date:24 August 2021

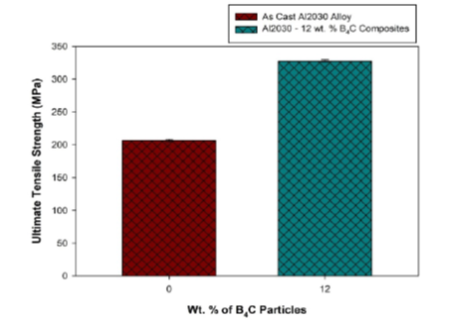

Objective: To synthesize and assess the mechanical behaviour of 12 wt. % of 80 to 90 micron sized B4C reinforced Al2030 alloy metal composites. Method: Al2030 alloy with 12 wt. % of B4C reinforced composites were developed by liquid melt stir cast method. These prepared composites were subjected to microstructural characterization by SEM, EDS and XRD. Mechanical properties like hardness, tensile and flexural strength were evaluated according to ASTM standards. Findings: Scanning electron micrograph of Al2030 alloy with 12 wt. % of B4C composites revealed the thorough distribution of boron carbide particles in the Al2030 matrix. EDS and X-ray diffractometer patterns confirmed the presence of boron carbide particles in the Al2030 alloy matrix. The addition of 12 wt. % of B4C particles enhanced the hardness by 74.8%, ultimate strength by 59.2%, yield strength by 64.8% and flexural strength by 44.2% with slight decrease in ductility. Novelty: Al2030 alloy is an aerospace grade aluminium alloy widely used for industrial applications. Advanced metal composites developed with the incorporation of 80 to 90 micron sized B4C particles in Al2030 alloy helps in weight reduction of aerospace components.

Keywords: Al2030 Alloy; B 4 C Particles; Microstructure; Tensile Strength; Flexural Strength; Fractography

© 2021 Anjan Babu et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.