Indian Journal of Science and Technology

Year: 2020, Volume: 13, Issue: 19, Pages: 1935-1943

Original Article

Khyati Patel1∗, Falguni R Patel2

1 Research Scholar, Department of Biotechnology and Microbiology, Shri M.M. Patel Institute of Sciences and Research, Kadi Sarva Vishwavidyalaya, Gandhinagar, Gujarat, India. Tel.: +91 740-531-8893

2 Assistant Professor, Department of Biotechnology and Microbiology, Shri M.M. Patel Institute of Sciences and Research, Kadi Sarva Vishwavidyalaya, Gandhinagar, Gujarat, India

∗Corresponding author:

Khyati Patel Research Scholar,

Department of Biotechnology and Microbiology, Shri M.M. Patel Institute of Sciences and Research, Kadi Sarva Vishwavidyalaya, Gandhinagar, Gujarat, India.

Tel: +91 740-531-8893

Email: [email protected]

Received Date:24 April 2020, Accepted Date:27 April 2020, Published Date:18 June 2020

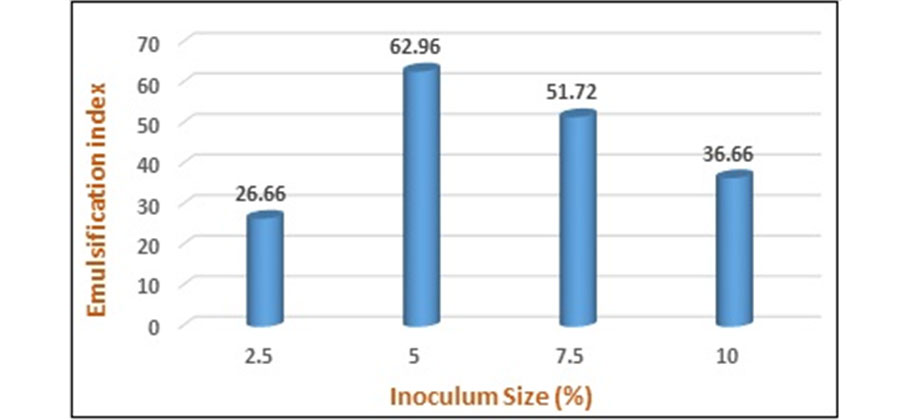

Objectives: Biosurfactants are surface active compounds capable of reducing surface tension and interfacial tension. The selection of low cost and renewable sources are essential for successful biosurfactant production. The aim of this study is to optimize the media and culture conditions for the biosurfactant production by Wickerhamomyces edaphicus using cottonseed oil as a single Carbon source. Methodology: W. edaphicus was isolated from the mangrove areas of Mundra, Gujarat, and screened for the production of biosurfactant by oil displacement test and emulsification index method. The production media were optimized for maximum biosurfactant production from W. edaphicus by optimizing the cultivation conditions such as carbon source, nitrogen source, temperature, pH and inoculum size. Findings: W. edaphicus could be a potential yeast for biosurfactant production using cottonseed oil as a carbon source. During the optimization process, the optimal growth parameters obtained were: cottonseed oil 4% (emulsification index: 66.8%) and yeast extract 0.1% (emulsification index: 63.33%) and the environment parameter were: temperature 30oC (emulsification index: 64.51%) and pH 6.0 (emulsification index: 66.54%). Novelty/Applications: Biosurfactant produced by W. edaphicus finds wide variety of applications in detergent, food , biotechnological, pharmaceutical and cosmetic industries, oil recover enhancement and bioremediation.

Keywords: Biosurfactant; cottonseed oil; emulsification index; oil displacement; Wickerhamomyces edaphicus

© 2020 Patel, Patel. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.