Indian Journal of Science and Technology

Year: 2023, Volume: 16, Issue: 12, Pages: 884-893

Original Article

Neelkanth Dhone1*

1Assistant Professor (Faculty), Production and Operations Management, Indian Institute of Management, 441108, Nagpur, India

*Corresponding Author

Email: [email protected]

[email protected]

Received Date:30 January 2023, Accepted Date:06 March 2023, Published Date:25 March 2023

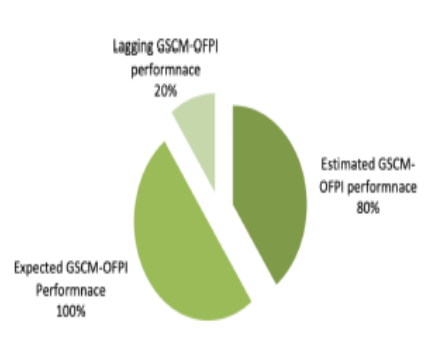

Objective: To measure the GSCM-Overall Fuzzy Performance Index (GSCMOFPI) of industry under integrated operations based GSCM module. Method: The author aids the Green Entrepreneurs (GEs) with Overall Fuzzy Performance Index (OFPI) approach to estimation the GSCM-OFPI of industry in the terms of Generalized Trapezoidal Fuzzy Set (GTFs), Crisp Value (CV) and % under proposed module. Finding: A hypothetical case research of gear manufacturing industry is exhibited to reveal the real life usage of presented research work. The GEs proposed the ideal limit of GSCM-OFPI such as 1 or 100% for benchmarking perspective. The findings are synchronized only with computation of GSCM-OFPI i.e., 0.80 in the terms of CV and 80 in %. GE is advised to accelerate GSCM-OFPI=0.20 to maintain future GSCM-OFPI. Work model is useful for finding GSCM-OFPI and work is limited only for mapping GSCM-OFPI of an individual firm. Novelty: A novel approach has been proposed to evaluate the GSCM-OFPI of a case study firm by overcoming the drawbacks of previous presented research forum, which added the unique features in research work.

Keywords: Module; Linguistic Information; Performance Measurement (PM); Overall Fuzzy Performance Index (OFPI); Green Supply Chain (GSC)

© 2023 Dhone. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.