Indian Journal of Science and Technology

Year: 2022, Volume: 15, Issue: 36, Pages: 1800-1807

Original Article

Sumalatha Chevva1, Sreenivasulu Reddy Tirumalareddygari2, Phaneendra Reddy Guddeti1,3, Tulasi Ramakrishna Reddy Kotte1*

1Solar Energy Laboratory, Department of Physics, Sri Venkateswara University, Tirupati-517502, India

2Department of Physics, Viswam Engineering College, Madanapalle-517325, India

3Department of Physics,, Dr. YSR Architecture and Fine Arts University, Kadapa-516002, India

*Corresponding Author

Email: [email protected]

Received Date:30 April 2022, Accepted Date:03 September 2022, Published Date:21 September 2022

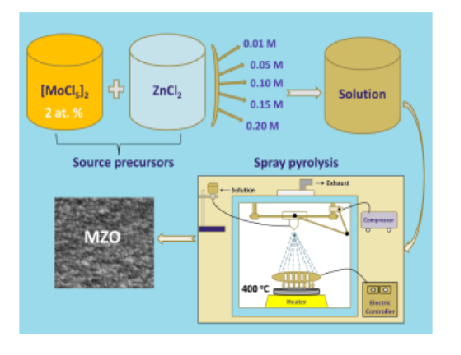

Objectives: Current research focuses on the role of precursor molarity effect on sprayed Mo-doped ZnO films and their suitability as window layers in solar cells. Methods: Molybdenum (Mo) doped zinc oxide (MZO) thin films were deposited by the technique of spray pyrolysis, varying the Zn molarity in the range, of 0.01 M to 0.20 M at a constant substrate temperature of 400 ◦C. The Mo doping concentration was constant at 2 at. %. Findings: The XPS studies witnessed the presence of Mo and Zn in +6 and +2 state respectively. The XRD pattern showed both (111) and (002) as strong peaks, confirming the hexagonal wurtzite crystal structure. The optical investigations showed that the MZO films with Zn molarity 0.10 M exhibited high optical transmittance having a wide energy band gap. Films with zinc molarity of 0.10 M showed low resistivity and high mobility. The prepared CTS/MZO hetero junction solar cells performance was studied by evaluating parameters such as open circuit voltage (Voc) of 0.14 V, short circuit current density (Jsc) of 6.46 mA cm-2, a fill factor (FF) of 0.27, and a conversion efficiency of 0.25 %. Novelty: Studies on the physical properties of Mo:ZnO layers such as Ritveld refinement analysis and Haze were reported first time. CTS/MZO hetero junction solar cells have not yet been published. The observed results are analogous to improve the efficiency of solar cells using environmentally benign materials.

Keywords: Spray pyrolysis; Thin films; XRD; Optical properties; Haze; Hall measurements

© 2022 Chevva et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.