Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 18, Pages: 1452-1467

Original Article

Khalid Zhani1*, Michel Darrieulat2, Ahmed Chenaoui1

1Department of Physics, Mechanical and Civil Engineering laboratory, Faculty of Sciences

and Technology, University Abdelmalek Essaadi, Tangier, Morocco, Tel.: +212667425574

2Mines Saint-Etienne, Univ Lyon, CNRS, UMR 5307 LGF, Centre SMS, F - 42023 Saint-Etienne

France

*Corresponding Author

Tel: +212667425574

Email: [email protected]

Received Date:21 January 2021, Accepted Date:17 April 2021, Published Date:19 May 2021

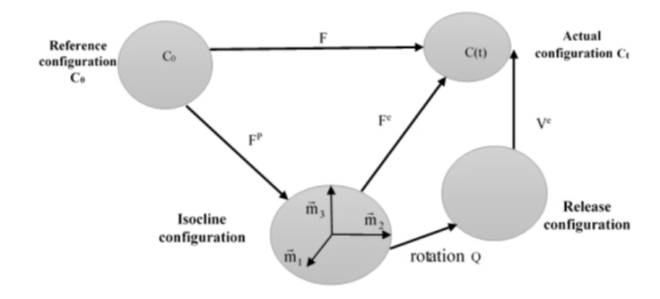

Objectives: The main objective of this work is the development of a mechanically coherent framework for the implementation of numerical simulation tools for sheet metal forming processes. The work at hand is part of a study of the mechanical behaviour of metallic materials subjected to large elastoplastic deformations during channel-die testing and a study of the mechanisms that limit their formability and cause their instability. We analyse the effect of induced rotation on the appearance of plastic instability predicted by Rice’s criterion. Methods: At the beginning, an adequate modelling of the mechanical behaviour of metals in large elasto-plastic deformations using the formalism in rotational referential is made. Then, a prediction of plastic instabilities is developed using Rice’s bifurcation criterion. Indeed, the integration of the law of anisotropic elastoplastic behaviour is presented in a three-dimensional kinematics framework in order to write the deformation tensor as a superior triangular matrix, with Hill’s anisotropic yielding function, using Runge Kutta’s method to integrate the obtained equations. Findings: we were able to show that Rice’s criterion can be used for any kind of material and that this criterion is effective in predicting what happens in metals. It predicts shear-band bifurcation in a continuous plastic medium. Hill’s criterion is suitable for what is weakly anisotropic. The model described above represents a good mathematical framework for analysing the behaviour of materials and plastic instability. Novelty: This study allows to apply Rice’s criterion in the case of a channel-die compression test, so as to locate plastic instability and see the appearance of shear bands for all types of materials; it demonstrates that the initial rotation of the material influences the appearance of shear-bands during a test simulating rolling.

Keywords: Elastoplastic; Large deformations; Anisotropy; Plastic instability; Localisation

© 2021 Zhani et al.This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.