Indian Journal of Science and Technology

Year: 2020, Volume: 13, Issue: 21, Pages: 2168-2174

Original Article

Rabboni Mike Government1∗, Edozie Thompson Okeke2 , Raphael Stone Odera3 , Amechi Kingsley Ani3 , Julius Thaddaeus4 , Nnaemeka Bernard Ikechukwu1

1 Department of Chemical Sciences, Federal University of Wukari, Wukari Taraba State, Nigeria

2 Department of Civil Engineering, University of Nigeria, Nsukka Enugu State, Nigeria

3 Department of Chemical Engineering, Nnamdi Azikwe University, Awka, Nigeria

4 Departments of Mechanical Engineering, University of Nigeria, Nsukka Enugu State, Nigeria

∗Corresponding author:

Rabboni Mike Government

Department of Chemical Sciences, Federal University of Wukari, Wukari Taraba State, Nigeria E-E-mail: [email protected]

Received Date:05 April 2020, Accepted Date:19 May 2020, Published Date:23 June 2020

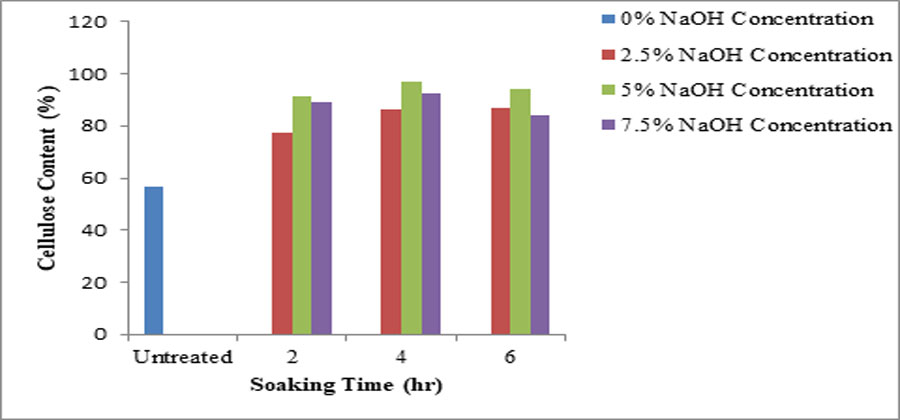

Background/Objectives: The minimization of unnecessary components from agro-waste is essential for performance and conversion into useful products in domestic and industrial utilization. The need for removal of these unwanted components is important to boost the strength of the agro-waste for its effectiveness as additive in agro-based polymer composite production as new engineering material for structural purpose. This investigation entailed the influence of NaOH concentration and soaking time on the key compositional content of novel mango seed shell fiber (MSSF). Methods/findings: The MSSF was treated with NaOH solution at 2.5, 5, 7.5 wt % concentration and soaking time of 2-6 hr. The compositions of MSSF were obtained for the treated and untreated sample by gravimetric method. The pure and NaOH treated MSSF were analyzed instrumentally employing Fourier transform infrared (FTIR) spectrometer to show the functionality of some substances present. From this result, the optimum composition of MSSF was observed at 5 % NaOH concentration and 4 hr soaking time. The maximum composition at this condition improved than the crude MSSF by 71.33% cellulose content, while the hemicelluloses and lignin content removal was lower than the raw fiber by 91.75 and 98.84%, respectively. Application: The results at this optimum treatment of MSSF composition can be recommended for agro-based polymer composite in indoor application.

Keywords: Mango seed shell fiber; composition; NaOH; agro-wastes; alkaline treatment

© 2020 Government, Okeke, Odera, Ani, Thaddaeus, Ikechukwu. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Subscribe now for latest articles and news.