Indian Journal of Science and Technology

DOI: 10.17485/IJST/v13i48.1974

Year: 2020, Volume: 13, Issue: 48, Pages: 4723-4731

Original Article

Md. Rubel Alam1, Tarikul Islam2*, Mahbubur Rahman3, Md. Abdullah Al Noman Antor4, Rifat Rahman4, Taslima Ahmed Tamanna5

1Department of Knitwear Manufacturing and Technology, BGMEA University of Fashion and Technology, Dhaka, Bangladesh

2Department of Textile Engineering, Jashore University of Science and Technology, Jashore, 7408, Bangladesh

3Department of Textile Engineering, Mawlana Bhashani Science and Technology University, Tangail, 1902, Bangladesh

4Department of Apparel Manufacturing and Technology, BGMEA University of Fashion and Technology, Dhaka, Bangladesh

5Department of Textile Engineering, BGMEA University of Fashion and Technology, Dhaka, Bangladesh

*Corresponding Author

Email: [email protected]

Received Date:31 October 2020, Accepted Date:22 December 2020, Published Date:04 January 2020

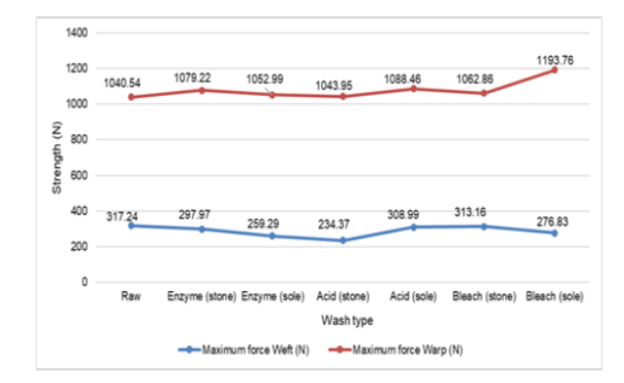

Background/Objective: Denim fabric is the most versatile dress material and acclaimed the most popular among the young generations due to its trendy looks. Since stone is being vastly used to improve the softness and comfort feeling along with fading effects, but bearing some problems. For instance, stone leads to deterioration of fabric strength, machine wear, and tear, grit deposition in the effluent plant, increasing labor cost to separate the stone powder from the pockets, and also harmful for the expensive laundry machine, etc. On the contrary, post-used rubber shoe soles are thrown or burnt which leads to ozone depletion. Therefore, this study was carried out to mitigate both the existing problems of stone washing and also this endeavor was done to find a suitable alternative of pumice stone. Methods: Washing was continued with both stones, collected rubber shoe sole against enzyme, acid, and bleaching agent. Eventually, washed garments have been tested and compared with the unwashed regular ones, based on visual appearance, degree of shade change, tensile strength, tear strength, abrasion resistance, and weight per unit area, and crimp interchange. Findings: Result reveals the satisfactory values, but the degree of shade changes against acid has poor value due to not having the absorption ability of potassium permanganate (KMnO4). Also, the result tellsthe noise intensity is much lower (68-72 dB) compared to stonewash (89- 90dB). Introducing the aforementioned alternative in denim washing, it shows the perfect results rather than stone one without compromising the trendy looks.

Keywords: Denim fabric; garments washing; physical and mechanical properties; sustainability

© 2020 Alam et al.This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.