Indian Journal of Science and Technology

DOI: 10.17485/IJST/v16i29.2443

Year: 2023, Volume: 16, Issue: 29, Pages: 2176-2182

Original Article

Mili S Shah1*, Manthan Panchal2, Ravi B Patel3, D K Bhoi4

1Research Scholar, Department of Chemistry, Silver Oak University, Ahmedabad, 380061, Gujarat, India

2Professor, Department of Chemistry, Silver Oak University, Ahmedabad, 380061, Gujarat, India

3Professor, Department of Chemistry, Shree P. M. Patel Institute of Post graduate Studies and Research in Science, 388001, Anand, India

4Professor, Department of Chemistry, J& J College of Science, Nadiad, 387001, India

*Corresponding Author

Email: [email protected]

Received Date:18 May 2023, Accepted Date:30 June 2023, Published Date:28 July 2023

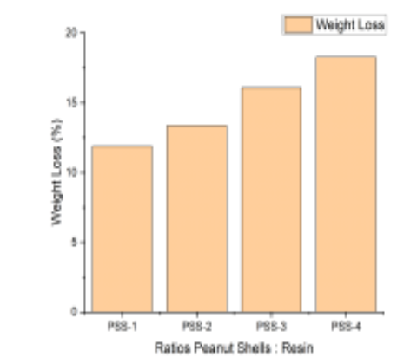

Objectives: To explore the use of natural composites as environmentallyfriendly alternatives to plastic. To investigate the effects of varying ratios of peanut shells and Styrene Diluted Unsaturated Polyester resin (SDUPR) on the mechanical properties of the composites and to assess the biodegradability of the composites. Method: Composites were prepared using the manual layup method. Utilized varying ratios of peanut shells and SDUPR as: 50:50, 55:45, 60:40, 65:35 and cured the composites with a curing agent. Performed mechanical tests including Izod Impact test, Flexural test, Rockwell Hardness test using standard test ASTM D256, Flexure strength testing and HR-210MR respectively. Evaluated the biodegradability of the composites. Findings: The ratio of peanut shells to SDUPR significantly affects the hardness and biodegradability of the composites. Comparisons of the four sheets provide insights into the mechanical properties of each composite and the impact of the ratio of peanut shells and SDUPR. The observed values of Izod impact test are 1.95 J/cm2, 1.86 J/cm2, 1.75 J/cm2, 1.69 J/cm2 and Rockwell hardness test are 29 kg.mm, 23 kg.mm, 17 kg.mm, 9 kg.mm. Novelty: This study explores the use of natural composites made of SDUPR and peanut shells, contributing to the search for environmentally-friendly materials. It provides valuable insights into the potential of natural composites as a sustainable alternative to conventional materials.

Keywords: Biodegradability; Composites; Peanut Shells; Polyester Resin

Shah MS, Panchal M, Patel RB, Bhoi DK. (2023) Utilization of Peanut Shells as Sustainable Fillers for Light Weight and Cost-Effective Composite Material . Indian Journal of Science and Technology. 16(29): 2176-2182. https://doi.org/10.17485/IJST/v16i29.2443

Subscribe now for latest articles and news.