Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 1, Pages: 80-89

Original Article

Md. Kaleem Sohail1, Ch. Naveen Reddy2*, J Suresh Kumar3

1M. Tech Student, Department of Mechanical Engineering, VNRVJIET, Hyderabad, 500090, Telangana, India

2Assistant Professor, Department of Mechanical Engineering, VNRVJIET, Hyderabad, 500090, Telangana, India

3Senior Professor, Department of Mechanical Engineering, JNTUH, Hyderabad, 500085, Telangana, India

*Corresponding Author

Email: [email protected]

Received Date:06 September 2023, Accepted Date:07 December 2023, Published Date:12 January 2024

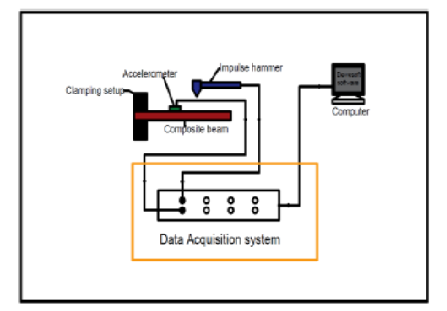

Objectives: To investigate the vibration characteristics of jute-banana fiber-reinforced hybrid composites by exploring the influence of surface pre-treatment with sodium hydroxide (NaOH) and coating with Polylactic acid (PLA) using Finite Element Analysis (FEA). Methods: Natural fiber reinforced composites (NFRC) have advantages over man-made fibers such as glass, carbon, and Kevlar. However, the hydrophilic characteristic of natural fiber results in poor adherence between fiber and matrix. This reduces the characteristics of the polymer composite. Before constructing the composite laminates, jute and banana fibers are coated with NaOH and Polylactic acid. Experimental vibration and Finite Element Analysis method is adopted to predict the natural frequencies under various end conditions, including Simply Supported (SS), Clamped (CC), and Clamped-Free (CF). Furthermore, it explores the influence of ply orientations on natural frequencies under SS and CC conditions. Findings: According to the results of the experiments and FEA, chemical treatment and coating increase the free vibration characteristics of composites by improving the interfacial connection between the fiber and the matrix. The experimental and FEA results are compared, revealing that fiber treatment and coating increase vibration qualities. Specifically, during the experimental study, the NaOH-treated and PLA-coated composites showed a 24.08% increase in natural frequency. Ansys data also showed significant increases of 6.57%, 8.1%, and 26.77% under SS, CC, and CF conditions compared to other specimens. Novelty: In this work, woven jute and banana fibers were subjected to eco-friendly and chemical treatment NaOH and PLA coating in order to improve the adhesion with the matrix thereby improving the performances of their composites. The present developed composites can be used for medium-strength applications in the field of automobile, construction and packaging.

Keywords: Jute and Banana Composites, NFRC, Free Vibration, Polylactic Acid Coating, NaOH treatment

© 2024 Sohail et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.