Indian Journal of Science and Technology

DOI: 10.17485/IJST/v15i30.1231

Year: 2022, Volume: 15, Issue: 30, Pages: 1495-1503

Original Article

K Nithyadevi1*, V Pandiyan2*

1Assistant professor, Department of Physics, Kunthavai Naacchiyaar Government Arts College for Women (Autonomous), Thanjavur-613007 Affiliated to Bharathidasan University, Palkalaiperur, Tiruchirappalli-620024, Tamil Nadu, India

2Assistant Professor, Nehru Memorial College (Autonomous), Affiliated to Bharathidasan University, Puthanampatti-621007, India

*Corresponding authors

Email: [email protected]

[email protected]

Received Date:17 June 2022, Accepted Date:27 June 2022, Published Date:09 August 2022

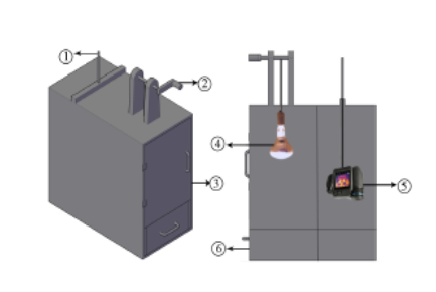

Objectives: To analyze the effect of potato starch infrared heating (IR) and the functional characteristics of the starch film. Methods: Potato starch was heated by IR heater at different time intervals (45 min, 65 min and 85 min) and starch was used to develop polymer films by the addition of glycerol as a plasticizing agent. The surface temperature of starch at different bed thickness was measured using a thermal imaging camera. The temperature of the starch varied from 72.77oC to 80.83oC. The functional properties of developed films were analyzed by their thickness, solubility, contact angle, puncture strength and coefficient of friction with different surfaces. Findings: The results indicate that the puncture strength of IR treated starch film varied from 2.5 to 3.79N and the value was found less in control recorded as 1.87N. The modified starch film thickness and opacity were increased from 0.11 to 0.128mm and 1.15 to 1.22 percent respectively. The solubility percent was found less in IR heated starch than in control. SEM and FTIR analysis results show that IR heat treatment has significant effect on morphology and functional characteristics of the starch film. Novelty: Infrared heating modified the structural characteristics of potato starch and improved the functional properties of the starch film.

Keywords: Starch film; Infrared heating; Functional; Physical; Mechanical

© 2022 Nithyadevi & Pandiyan. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.