Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 16, Pages: 1633-1642

Original Article

Chandan Waghmare1*, Santosh Patil1, Pruthviraj Chaudhari2

1Assistant Professor, RIT, Islampur, 415409, Maharashtra, India

2Research Scholar, RIT, Islampur, 415409, Maharashtra, India

*Corresponding Author

Email: [email protected]

Received Date:13 March 2024, Accepted Date:25 March 2024, Published Date:15 April 2024

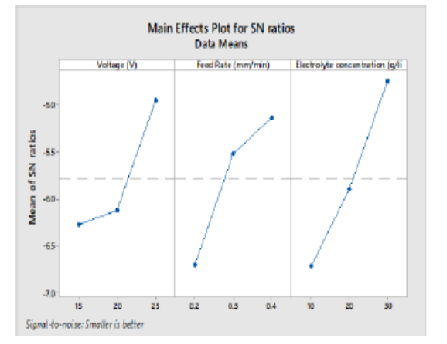

Objectives: To evaluate the significance of advanced machining techniques, such as EDM, ECM, and USM, in increasing productivity and overcoming challenges associated with outdated Al-SiC MMC machining. To assess the surface roughness, tool wear, and machining cost implications of employing advanced machining methods for Al-SiC MMCs. Methods The parameters studied were voltage (V), feed rate (F), and electrolyte concentration (C) in electrochemical machining (ECM) of Al/15%SiC composites. To optimise process parameters, the Taguchi method for Design of Experiments (DOE) with an L27 orthogonal array was used. Signal responsiveness is optimised using the Taguchi approach. The Technique for Order Preference by Similarity to the Ideal Solution (TOPSIS) is used to find optimal machining settings. Findings: The outcome of this research is that the parameters affecting surface roughness and material removal rate are voltage, electrolyte concentration and feed rate. The minimum Surface Roughness achieved by selecting the best combination level is A2, B3, C3 (smaller is better) i.e., voltage 20 V, feed rate (f) 0.4 mm/min., electrolyte concentration (c) 30 g/lit. The maximum Material Removal Rate achieved by selecting the best combination level is A3, B3, C3 (larger-is-better) i.e., voltage 25V, feed rate (f) 0.4 mm/min., electrolyte concentration (c) 30 g/lit. Novelty : In this work, TOPSIS technique paired with Taguchi method is used which is rarely studied by other researchers. TOPSIS technique provides the best optimal solution as compared to other techniques.

Keywords: Al-SiC MMCs, ECM, MRR, Ra, Taguchi method, TOPSIS

© 2024 Waghmare et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.