Indian Journal of Science and Technology

Year: 2022, Volume: 15, Issue: 12, Pages: 535-541

Original Article

Sanjaykumar Dalvi1*, Swati Sonawane2

1Head of Physics Department, S. N. Arts, D.J. M. Commerce & B. N. S. Science College (Autonomous), 422605, Sangamner, India

2Assistant Professor, Department of Chemistry, H. P. T. Arts and R. Y. K. Science College, 422005, Nashik, India

*Corresponding Author

Email: [email protected]

Received Date:07 February 2022, Accepted Date:21 February 2022, Published Date:25 March 2022

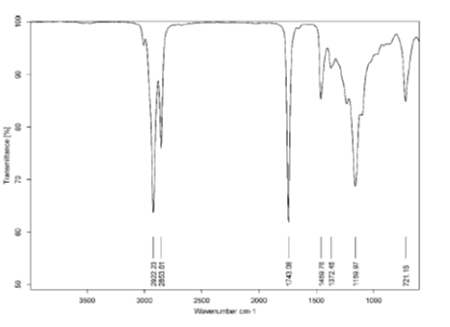

Objectives: To study the single step in-situ transesterification process for synthesis of fatty acid methyl ester (biodiesel) from microalgae biomass Chlorococcalean Chlorella vulgaris. Methods: The growth and lipid productivity of an isolated microalgae C. vulgaris were studied under Chu‘s 10 modified media under phototrophic cultivation conditions. In-situ transesterification of this dry biomass with methanol in presence of base catalyst at 60 º C was carried out to investigate the fatty acid methyl ester’s biochemical composition by FTIR & analysis performed using GCMS technique. The cetane number was also calculated. Findings: The biodiesel fraction from C. vulgaris biomass was found to be 85.58%. The 43.40% lipid fraction was obtained from the biomass of C. vulgaris. In the in-situ transesterification process, the optimal concentration of potassium hydroxide (KOH) and methanol yields an 85.58 percent biodiesel fraction. The presence of lipid compounds and the biochemical composition of fatty acid methyl ester were verified with the help of FTIR spectral analysis. The gas chromatography-mass spectrometry analysis explores the fatty acid methyl ester profile, which comprises 29.05% and 56.54 percent saturated and unsaturated FAMEs. Through GCMS, the fatty acid methyl ester composition of C. vulgaris microalgae species was revealed through six types of fatty acid methyl esters, of which 54.95%, 11-octadecenoic acid methyl ester, is the dominant one. The cetane number of C. vulgaris biodiesel was determined to be 67.726; this is comparable to diesel fuel according to ASTM-D613, and the presence of a higher fatty acid methyl ester composition indicates favourable biofuel qualities. Novelty: The calculation of cetane number by theoretical method and affirmation of ecofriendly single step in-situ transesterification method for biodiesel production.

Keywords: Chlorococcalean Chlorella vulgaris; Biodiesel; GCMS; FTIR; Cetane Number

© 2022 Dalvi & Sonawane. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.