Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 4, Pages: 333-342

Original Article

R Prakash1*, N Divyah2, V Selvapriya2, P Mahakavi3

1Department of Civil Engineering, Government College of Engineering, Tirunelveli, 627007, Tamil Nadu, India

2Department of Civil Engineering, PSG Institute of Technology and Applied Research, Coimbatore, 641 062, Tamil Nadu, India

3Amity School of Engineering and Technology (ASET), Amity University, Madhya Pradesh, India

*Corresponding Author

Email: [email protected]

Received Date:10 November 2023, Accepted Date:30 December 2023, Published Date:20 January 2024

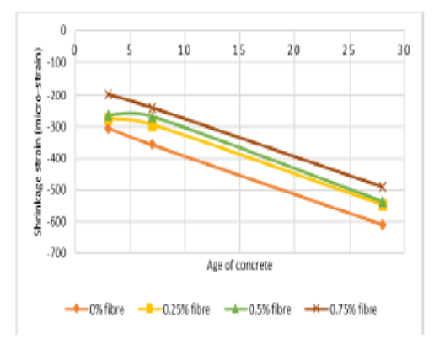

Objectives: The research explores the effect of adding polypropylene fiber in foamed concrete. Methods/Analysis: The manuscript discusses the mechanical and durability properties of polypropylene fiber reinforced foamed concrete. Fly ash, copper slag, and polypropylene fiber were admixed for strengthening the foamed concrete. The experimental analysis is carried out with polypropylene fibers at 0%, 0.25%, 0.5% and 0.75% by volume of concrete. Image processing analysis through MATLAB was done to validate the mechanical and durability properties. Findings: The results showed that, the optimum quantity of fiber reinforcement is found to be 0.25%. There was an increase in compressive, split tensile strength and flexural strength of 13.6%, 16.7%, and 30%, respectively, with 0.25% fiber. The durability test results suggest that these values are acceptable for constructing durable concrete structures limited to non-structural applications. The results were validated using image processing analysis through MATLAB software. Economic analysis showed that the foamed concrete reduces the structural dead load by almost 35.3%. Novelty/Improvement: It is recommended that the polypropylene fiber reinforced foamed concrete would be feasible for durable concrete structures limited to non-structural applications.

Keywords: Foamed concrete, Polypropylene fiber, Shrinkage, Image processing, Structural viability

© 2024 Prakash et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.