Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 2, Pages: 171-183

Original Article

C Yugeshwar1, M V R D Prasad1, M Venkata Ramana2*

1Department of Mechanical Engineering, VNR Vignana Jyothi Institute of Engineering and Technology, Hyderabad, Telangana, India

2Department of Automobile Engineering, VNR Vignana Jyothi Institute of Engineering and Technology, Hyderabad, Telangana, India

*Corresponding Author

Email: [email protected]

Received Date:27 October 2023, Accepted Date:12 December 2023, Published Date:12 January 2024

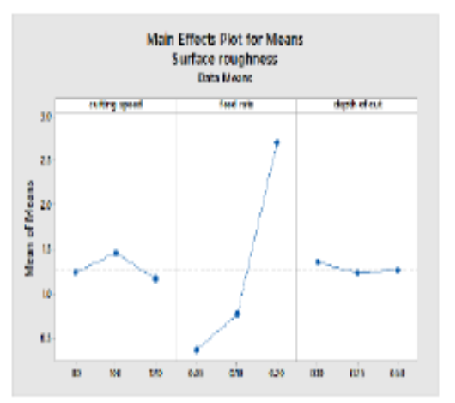

Objectives: To optimize the process parameters in dry turning of hardened 20MnCr5 using a PVD coated insert to minimize surface roughness and power consumption and maximize material removal rate using the Taguchi technique and machine learning model. Methods: For carrying out the experiments, an L27 orthogonal array was employed and Taguchi’s means of mean method was used to find the optimal condition. ANOVA was utilized for determining the significance of factors. The Random Forest model uses an ensemble learning method where multiple decision trees are developed and then predictions are made. To boost the prediction efficiency, averages are made from these multiple decision trees and the voting method to finalize the model that needs to be used for the prediction. Finally, experimental and predicted values are compared using statistical metrics to determine the model's effectiveness. Findings: From experimental data at 80 m/min, 0.2 mm/rev, 0.5 mm and 120 m/min, 0.05 mm/rev, 0.25 mm and 100 m/min, 0.2 mm/rev, 0.1 mm are the optimal conditions found for material removal rate, surface roughness and power consumption respectively. Feed was the most influential factor, with a percentage contribution of 90.98%, 46.86% and 87.053% for surface roughness, material removal rate and power consumption respectively. The developed random forest models had an accuracy of 91.057%, 96.546% and 96.0122% for surface roughness, power consumption and material removal rate respectively, and they had less mean absolute errors. Novelty: Alloy steels are used to manufacture components that need to resist wear and plastic deformation, so it’s important to know how hardened material behaves under dry turning operations as the world is focusing on green manufacturing. Moreover, the experimental approach is time-consuming and costly, so a machine learning model was developed based on the available experimental data to predict the output responses for additional inputs.

Keywords: Dry turning, MQL machining, Taguchi technique, ANOVA, Random Forest model

© 2024 Yugeshwar et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.