Indian Journal of Science and Technology

DOI: 10.17485/IJST/v16i45.2567

Year: 2023, Volume: 16, Issue: 45, Pages: 4131-4140

Original Article

Rani Kumari1, Kavita Saini2*

1Research Scholar, SCSE, Galgotias University, NCR, Delhi, India

2Professor, SCSE, Galgotias University, NCR, Delhi, India

*Corresponding Author

Email: [email protected]

Received Date:10 October 2023, Accepted Date:07 November 2023, Published Date:05 December 2023

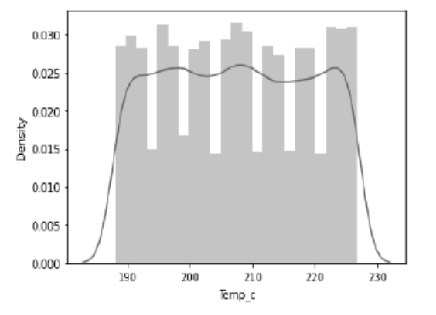

Objectives: The objective of the research is to focus on the quality product of injection molding for the automobile industry. The root cause of the defects in the product needs to be understood in order to improve the product quality. Method: The research represents an industry Standard Process for Data Mining (CRISP-DM) framework for molding quality improvement. The Logistic Regression, AI ML algorithm has been used to develop the model. Because Logistic Regression is a classification supervised algorithm and our dependent variable also belongs to classification so used this algorithm. Splits the data set for training (66.66%) and testing (33.33%) of the model. Findings: During the literature review, it was found that some of the researchers focused on minimizing the variation in the product quality by considering the filling and packing stage, but only these parameters' impact on product quality is not sufficient. Considering the limitation as done by many researchers, the presented research work on molding parameters. The presented research considers multiple process-independent variables and their range as mould weight, the temperature of mold and material, injection time, hold time, plastification time, cooling time, and total cycle time and one dependent variable like quality. Novelty: The novelty of this research is that it is detailing and focus on the quantity of molded items and all independent parameters that impact the dependent parameter (quality) of molded items during the injection molding process. Therefore, this model performs the prediction of the molded items’ quality based on their parameter values and sends an alarm or notification to the respective teams. The analysis has been done based on a pattern they find from a machine or database, and it returns the outcome, which can be a prediction.

Keywords: Predictive Analytics, Predictive Injection Molding, Data Mining, Machine Learning, Descriptive Data Mining, Predictive Data Mining

© 2023 Kumari & Saini. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.