Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 21, Pages: 1758-1774

Original Article

Rohit Navale 1 , Amarsinh Kanase Patil 1 , Jayesh Minase 1 , Amar Pandhare✉ 1

1Department of Mechanical Engineering, Sinhgad College of Engineering,Pune, 411041,India

Received Date:31 March 2021, Accepted Date:29 April 2021, Published Date:19 June 2021

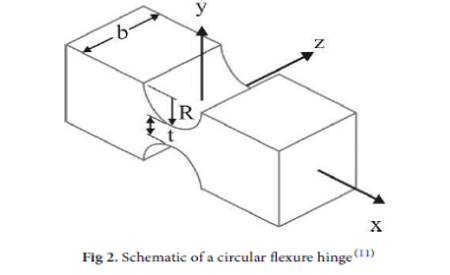

Background: The piezoelectric motion with multi-degree of freedom is gaining attention in industries for modern manufacturing. High degree of positioning accuracy is obtained by complaint micro machining stages which involves high cost. A variety of stages of multi-degree motion freedom are proposed and applied for decades which can perform very high precision outputs in a wide travel range. Methodology: This paper mainly focuses on design, development and analysis of the 3 DOF (Degree of Freedom) XYqZ micro-motion stage. The role of each component of the stage is discussed. The various design processes are discussed and includes the discussion about the inputs to the design process as well as the constraints; both of which are dependent on the application for which the stage is used. Based on the design rules, an iterative optimization process is implemented and three design options are presented. Findings: The finite element modeling of all the design options are carried out. This is followed by performing deformation, static, fatigue and modal analysis on the three design options. The deformation analysis predicts that design 1 and design 2 offer a workspace of around 210 µm each along (X, Y) direction and 25 µrad along the Z direction while design 3 has deformation of 125 µm each along (X, Y) direction while 25 µrad along Z direction where as the fatigue analysis presented shows the life of around 105 cycles. Novelty: Using this technique the micro-motion stage is achieved for three degrees of freedom.

Keywords

Micro motion stage, flexure hinges, modeling, 3 degrees of freedom

© 2021 Navale et al.This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.