Indian Journal of Science and Technology

DOI: 10.17485/IJST/v16i40.1651

Year: 2023, Volume: 16, Issue: 40, Pages: 3491-3501

Original Article

Prashant Veer1*, S C Vettivel2, Jatinder Madan2, B S Pabla3, Leema Nelson4

1Post Graduate Student, Department of Mechanical Engineering, National Institute of Technical Teachers Training and Research, 160019, Chandigarh, India

2Department of Mechanical Engineering, Chandigarh College of Engineering and Technology (Degree Wing), Chandigarh, 160019, India

3Department of Mechanical Engineering, National Institute of Technical Teachers Training and Research, Chandigarh, 160019, India

4Chitkara University Research and Innovation Network (CURIN), Chitkara University Institute of Engineering & technology, Chitkara University, Punjab, India

*Corresponding Author

Email: [email protected]

Received Date:12 August 2023, Accepted Date:04 September 2023, Published Date:27 October 2023

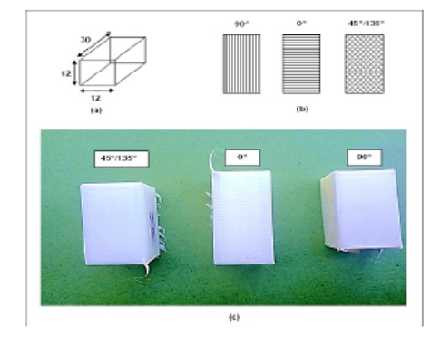

Objective: Investigating the effects of Deep Cryogenic Treatment (DCT) on the mass wear of 3D printed Thermoplastic Polyurethane (TPU) for application in knee spacers. Methods: Extrusion Temperature (ET), Print Speed (PS), Layer Thickness (LT), and Raster Orientation (RO), were the parameters used in this study. The mass wear of untreated and DCT TPU was obtained. The surface images were obtained through a Scanning Electron Microscope (SEM) and analyzed in the Gwyddion AFM software to investigate the surface texture, waviness, and roughness of the untreated and treated TPU. Findings: DCT decreased mass wear in 3D-printed TPU specimens. A higher ET (250 °C) yielded superior mass wear performance - conversely, higher PS elevated mass wear, with an optimal print speed of 15 mm/s. The most negligible mass wear was observed at 0.1 mm LT. The angle of RO exhibited significance with a 45°/135° RO orientation. Notably, PS demonstrated the most significant influence on mass wear for untreated TPU (61.11%), while for treated TPU, ET exerted the most substantial impact (90.61%). These insights were validated through analysis of variance (ANOVA) and regression modeling, indicating the robustness of the findings. Novelty: To date, injection-molded ultra-high molecular weight polyethylene (UHMWPE) is deployed for knee spacers. However, its rapid wear, time-consuming, and expensive fabrication techniques are a significant concern in total knee replacement surgeries. For the first time, this study combined 3D printing and deep cryogenic treatment to fabricate and characterize the tribological performance of biocompatible TPU for its potential application in knee spacers. This novel approach involved cryogenically treating the 3D-printed TPU wear specimens, which displayed superior wear performance to injection-molded UHMWPE. This affirmed the suitability of the combined 3D printing and cryogenic treatment for TPU as a potential alternative to the current methods and material for knee spacer applications.

Keywords: 3D Printing, Deep Cryogenic Treatment, Thermoplastic Polyurethane, Mass Wear, Surface Characterization

© 2023 Veer et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.