Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 14, Pages: 1419-1429

Original Article

S Jothi Arunachalam1, R Saravanan1*

1Department of Mechanical Engineering, Saveetha School of Engineering, Saveetha Institute of Medical and Technical Sciences, Saveetha University, Chennai, Tamil Nadu, India

*Corresponding Author

Email: [email protected]

Received Date:14 February 2024, Accepted Date:08 March 2024, Published Date:03 April 2024

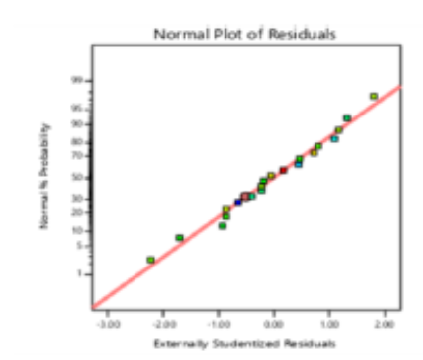

Objective: The prime goal of this study is to conduct a comprehensive analysis, modelling, and optimization of various independent factors and coming up with a material that suits in structural application in automobile. Method: Composite is prepared using hand lay-up technique. The analysis is carried out through the utilization of the Central Composite Design (CCD) approach. Mathematical models are formulated for ultimate tensile strength and impact resistance, employing the RSM. These factors include fiber orientation, fiber sequence, and filler percentage, with a focus on their influence on mechanical properties. Finding: These models act as valuable tools for the selection of the most favourable independent variables to maximize the mechanical properties related to tensile strength and impact resistance. In conclusion, the experimental findings emphasize that the inclusion of Nano-filler results in an enhancement of 20% and 36% on tensile strength and impact properties respectively. Novelty: TiO2-infused polymers exhibit unparalleled strength and flexibility, promising transformative advancements in this work that can be implemented in aerospace, indoor, automobile, and medical industries.

Keywords: Titanium dioxide, Nanofiller, Hybrid composite, Response surface methodology, Epoxy

© 2024 Arunachalam & Saravanan. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.