Indian Journal of Science and Technology

Year: 2022, Volume: 15, Issue: 42, Pages: 2230-2239

Original Article

P J Patil1*, P G Inamdar2, K D Joshi1, P V Mulik1, M R Jadhav1

1Assistant Professor, Tatyasaheb Kore Institute of Engineering and Technology, 416113, Warananagar, India

2M.Tech Student, Tatyasaheb Kore Institute of Engineering and Technology, 416113, Warananagar, India

*Corresponding Author

Email: [email protected]

[email protected]

Received Date:30 March 2022, Accepted Date:21 September 2022, Published Date:10 November 2022

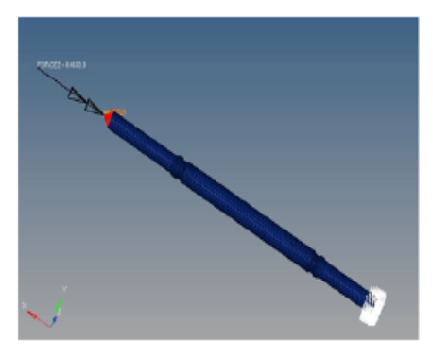

Objective: The prime objective of this study is to find out the best replacement for a conventional Steel front drive axle to reduce its weight and to verify its suitability for vehicular application. The study also aims to suggest appropriate Composite material and the best manufacturing technique for the proposed axle. Methods: Front drive axle of Maruti Alto 800has been selected for analysis which is carried out by Experimental and Fe method, 3D CAD model for this purpose has been prepared in CATIA V5. In ANSYS preprocessor, boundary conditions have been applied on FE model of front drive axle to simulate actual working conditions. Experimental analysis of the axle, manufactured with reinforced composite is carried out by strain gauge technique. Findings: The comparative study of results obtained by FE method and experimental technique has been carried out to estimate percentage error between them. The study shows that there is a fairly good agreement between these results. The maximum error recorded is within 0.46%. Angular deformation and the stresses generated in the axle made up of only composite are larger than these in steel axle. Reinforcement is necessary in order to get benefits of weight reduction as well as strength. Composite material with the specification 54% SiO2 -15% Al2O3 -12% CaO is one of the best combinations for the replacement of steel front drive axle. The drive axle made up of steel with 5 mm coating of aforementioned composite material is the best replacement for a steel axle of Alto 800. Novelty: A 41% reduction in heaviness is possible by substituting the conventional steel [SM45C] front drive axle of by the one made up of reinforced composite. Keywords: Front drive axle; FE analysis; Strain gauge analysis; Composite reinforcement

© 2022 Patil et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.