Indian Journal of Science and Technology

DOI: 10.17485/IJST/v14i28.1046

Year: 2021, Volume: 14, Issue: 28, Pages: 2368-2379

Original Article

M S Vinay1,2*, S Ranganatha3, Madeva Nagaral4

1Research Scholar, Mechanical Engineering Department, University Visvesvaraya College of

Engineering, Bangalore University, Bangalore, India

2Assistant Professor, Mechanical Engineering Department, School of Engineering,

Dayananda Sagar University, Bangalore, India

3Professor, Mechanical Engineering Department, University Visvesvaraya College of

Engineering, Bangalore University, Bangalore, India

4Deputy manager, Aircraft Research and Design Centre, HAL, Bangalore, India

*Corresponding Author

Email: [email protected]

Received Date:07 June 2021, Accepted Date:04 July 2021, Published Date:24 August 2021

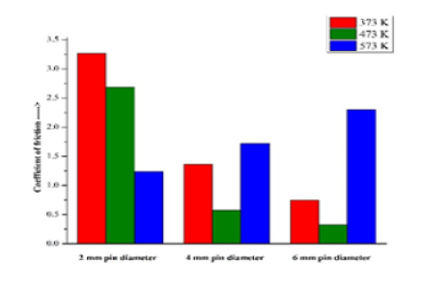

Objective: Aluminium and its alloys components are used in aero and space industries where in many cases trioboloading prevails. In space application, in addition to triboloading, the components should also perform in the absence of atmosphere. In the present investigation, attempted has been made to simulate the field conditions in the laboratory by sliding Al6061 alloy pin of different diameters in a vacuum at different temperatures using a vertically configured pin-on-disc test rig. Method: The pin diameters were 2, 4, and 6mm and the testing temperatures were 373, 473, and 573K. The normal contact pressure was 0.625MPa and the sliding speed was 0.5ms-1 and both were constant throughout the experiment. The coefficient of friction was monitored using a PC and the worn pin surface was studied in scanning-electronmicroscope. Findings: The result showed that the coefficient of friction at sliding temperatures 373 and 473K was found to be dependent on apparent contact area i.e., pin diameters 2, 4, and 6mm. The coefficient of friction was found to be 3.27 and 2.69 for pin diameter 2mm at temperature 373 and 473K whereas the coefficient of friction was of the range 1.36 to 0.33 for the pin of diameter 4 and 6mm. The scanning-electron-microscopic study revealed uniform plastic deformation for pin diameter of 2mm and non-uniform plastic deformation accompanied with abrasion extrusion phenomenon for the pin of diameters 4 and 6mm. The coefficient of friction at sliding temperature 573K was found to be insensitive to the apparent contact area. The coefficient of friction was in the range of 1.24 to 2.30. The SEM study revealed a large scale of non-uniform plastic deformation accompanied by abrasion, tearing of ridges, extrusion of both ridges, and entrapped wear debris. Novelty: It is a generic study for understanding the response of aluminium for tribo loading which.

Keywords: Pin on Disc (POD); Scanning Electron Microscope (SEM); High Temperature; Vacuum; Coefficient of Friction; Al6061 Aluminium Alloy 1

© 2021 Vinay et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.