Indian Journal of Science and Technology

DOI: 10.17485/IJST/v16i23.2258

Year: 2023, Volume: 16, Issue: 23, Pages: 1754-1759

Original Article

Jayson F Cariaga1*, Alvin G Domingo2, Bjorn S Santos3, Shirley C Agrupis4

1Researcher, National Bioenergy Research and Innovation Center, Mariano Marcos State University

2Student Researcher, Graduate School, Mariano Marcos State University, Mariano Marcos State University

3Researcher, Graduate School, Mariano Marcos State University

4Researcher, National Bioenergy Research and Innovation Center, Mariano Marcos State University

*Corresponding Author

Email: [email protected]

Received Date:05 December 2022, Accepted Date:08 April 2023, Published Date:17 June 2023

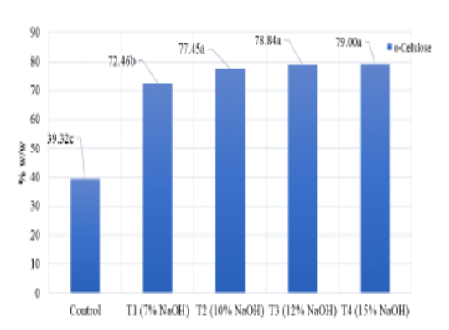

Objective: The aim of this research is to create a versatile approach to produce cellulose from nipa fronds, which are a sustainable resource. Methods: The study focuses on determining the amount of cellulose in nipa fronds, the effectiveness of a simplified physicochemical pretreatment, and the purity of the isolated nipa a-cellulose. The nipa biomass was pretreated using physical and chemical methods and analyzed through gravimetric analysis to determine its composition, delignification efficiency at varying concentrations of Sodium hydroxide (NaOH), and the purity of the isolated nipa a-cellulose (iNaC) using the National Renewable Energy Laboratory (NREL) protocol, ”NREL/TP-510- 42618”. The data was statistically analyzed using One-way Analysis of Variance. Findings: The results showed that increasing the concentration of NaOH led to positive responses in delignification, decreased hemicellulose, and increased recovery of cellulose. The study found that as the concentration of NaOH increased, the amount of a-cellulose recovered also increased. Treatment 4 (15% NaOH) and Treatment 2 (10% NaOH) produced 79% w/w and 77.45% w/w of a-cellulose, respectively. While Treatment 4 was highly effective in breaking down nipa biomass, a statistical analysis revealed that Treatment 2 produced comparable results in terms of producing pulp from nipa frond biomass without requiring higher concentrations of NaOH. This led to a reduction in chemical waste, making Treatment 2 a more sustainable option.

Keywords: a-cellulose; Nipa Frond; Biomass; Soda Treatment; Lignocellulosic; NREL protocol

© 2023 Cariaga et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.