Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 9, Pages: 852-862

Original Article

Abhay S Gore1*, Nilesh G Patil2, Mohammed Naser Farooqui3

1Research Scholar, Department of Mechanical Engineering, Maharashtra Institute of Technology, Chh. Sambhajinagar, Maharashtra, India

2Director, Department of Mechanical Engineering, Maharashtra Institute of Technology, Chh. Sambhajinagar, Maharashtra, India

3Assistant Professor, Department of Mechanical Engineering, Maharashtra Institute of Technology, Chh. Sambhajinagar, Maharashtra, India

*Corresponding Author

Email: [email protected]

Received Date:13 December 2023, Accepted Date:04 February 2024, Published Date:23 February 2024

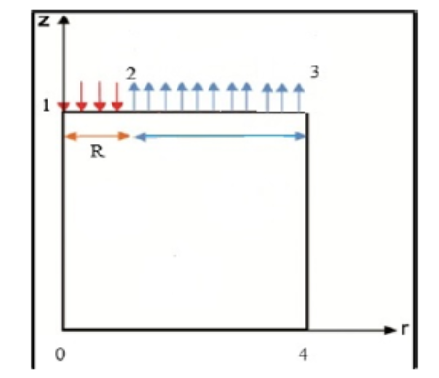

Objectives: A mathematical model is formulated for WEDM process for machining of Al/SiC/p to predict crater size, material removal rate for single spark discharge and same model is extended for multiple spark discharges which is not extensively studied in the literature. This was done by considering previous experimental data from the literature. Methods: A mathematical model predicts heat flux, radius of crater, material removal rate. Mode of heat transfer considered as conduction through workpiece. Material modeling is done considering the number of reinforced particles in the given volume. For random distribution of reinforced particles, a code is written in MATLAB software tool. Co-ordinates of these reinforced particles are extracted for FEA simulation in ABAQUS software tool. Material properties are considered as temperature dependent. This methodology is not adopted for MMCs. Findings: Results of theoretical model, FEA simulation and experimentation are compared. The predicted MRR by FEA simulation is 2% error at lower Ton values as 0.2µs and 0.4 µs to that of experimental MRR. Novelty: Crater size becomes shallow with increase in volume percentage of SiC particles resulting greater crater radius. With increased pulse on time MRR increases up to certain limit and then decreases.

Keywords: WEDM, Modeling, MMC, FEA, MRR

© 2024 Gore et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.