Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 5, Pages: 451-456

Original Article

Vandana N Mahajan1*, M J Sable2, S P Shekhawat3, Suhas R Patil4

1Department of Mechanical Engineering, Government College of Engineering, Jalgaon, 425002, Maharashtra, India

2Department of Mechanical Engineering, COEP Technological University, Pune, 411 005, Maharashtra, India

3Department of Mechanical Engineering, G. H. Raisoni Institute of Engineering and Business

Management, Jalgaon, 425002, Maharashtra, India

4Department of Physics, Dr. Annasaheb G. D. Bendale Mahila Mahavidyalaya, Jalgaon, 425001, Maharashtra, India

*Corresponding Author

Email: [email protected]

Received Date:10 September 2023, Accepted Date:03 January 2024, Published Date:31 January 2024

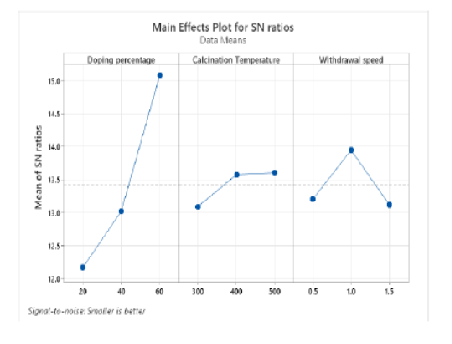

Objectives: To determine the best combination of blends of TiO2 /ZnO coated on SUS for obtaining a minimum corrosion rate. Methods: Different TiO2 /ZnO thin film blends are coated on SUS 304 substrates. The sol-gel dip-coating process is used for coating application. Also, withdrawal rates, calcination temperature, and doping percentage are the parameters used for the study of the anti-corrosion property. L9 array, using the Taguchi method, is applied for the design of the experiment. P.G-Lyte 1.0 model was used for the anticorrosion test. The Potentiosatic polarization method was applied for anti-corrosion testing. Findings: The results show that the percentage of ZnO doping (60%, 40%, and 20%) is the most significant factor in controlling the corrosion of the sample with plate number 1. The withdrawal rate (0.5 mm/sec, 1 mm/sec, and 1.5 mm/sec) has a minimal impact on the corrosion rate of the coated sample. The calcination temperature (300◦C, 400◦C, and 500◦C) has a greater impact than the withdrawal rate. There is a good agreement between the predicted and actual corrosion current. Novelty: Investigation of mechanical properties like corrosion resistance is essential for increasing the durability of automobile components by applying a coating of blends of TiO2 and ZnO with a rare blending combination that was not applied before for the investigation. In this research, efforts are made to reduce the corrosion rate by applying different blends of TiO2 and ZnO. Also, withdrawal rate and calcination temperature are varied in the process which was also not considered in the earlier studies.

Keywords: Taguchi method; Corrosion current; Signal to Noise ratio; Coating; Design of experiments

© 2024 Mahajan et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.