Indian Journal of Science and Technology

DOI: 10.17485/IJST/v17i11.2686

Year: 2024, Volume: 17, Issue: 11, Pages: 1059-1069

Original Article

G B Sathishkumar1*, B Asaithambi2, V Srinivasan3

1Research Scholar, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, Chidambaram, 608002, Tamil Nadu, India

2Assistant Professor, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, Chidambaram, 608002, Tamil Nadu, India

3Associate Professor, Department of Manufacturing Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalai Nagar, Chidambaram, 608002, Tamil Nadu, India

*Corresponding Author

Email: [email protected]

Received Date:23 January 2024, Accepted Date:12 February 2024, Published Date:05 March 2024

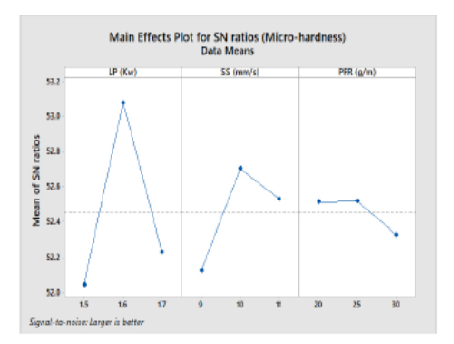

Objective: To investigate the mechanical and tribological behaviors of the surface-modified AZ61 alloy reinforced with Inconel 625 using the laser cladding method. Methodology: Surface modification was done with the help of a laser cladding machine by changing the input parameters such as Laser Power (LP), Scanning Speed (SS) and Powder Feed Rate (PFR). Experimentation was done as per L9 Taguchi design, and Grey Relational Analysis (GRA) was used to optimize the input parameters of surface-modified AZ61 alloy reinforced with Inconel 625 particles for measuring the output responses microhardness and wear rate. Findings: Based on the experimental findings, it was observed that laser power accounts for 76.13% of the variation in microhardness, while the powder feed rate predominantly affects wear volume, influencing it by 61.9%, as confirmed by grey relational grade analysis. To identify the most suitable processing parameters across different objectives, this study employs the grey relational method. The outcomes indicate that the microhardness and wear volume of the composite are notably impacted by the Inconel 625 powder feed rate. By integrating Grey relational analysis with multiple optimization objectives, a transparent method is established, resulting in a clad material with higher microhardness and reduced wear volume. The optimized processing parameters forecasted grey relational grades with a negligible error rate of 1.89%, with a significant contribution of 75.17% attributed to laser power. This investigation underscores the potential of multi-objective optimization in improving the mechanical properties of laser-cladded surfaces and establishes a theoretical framework for this approach. Novelty: This research work exhibits a unique method to modify the surface of the substrate by reinforcing Inconel 625 particle as a dense coating by adopting laser cladding technique.

Keywords: Inconel 625, Laser Cladding, Optimization, GRA

© 2024 Sathishkumar et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.