Indian Journal of Science and Technology

DOI: 10.17485/IJST/v13i35.1246

Year: 2020, Volume: 13, Issue: 35, Pages: 3605-3611

Original Article

Le Huy Hai1*, Le Mai Xuan Truc2, Nguyen Quoc Trung3

1Faculty of Chemical Engineering and Food Technology, Nguyen Tat Thanh University, VietNam

2Faculty of Chemical Engineering and Food Technology, HCMC University of Technology, VietNam

3Faculty of Chemistry, VNUHCM–University of Science, Ho Chi Minh City, Viet Nam

*Corresponding Author

Email: [email protected]

Received Date:26 July 2020, Accepted Date:13 September 2020, Published Date:29 September 2020

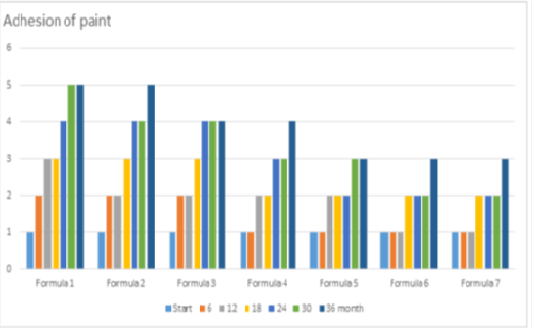

Objectives: Nanomaterials are currently being studied and used in paints. The purpose of this study is to investigate the properties of alkyd paint to protect metal when replacing CaCO3 by nanomaterial. Methods/ analysis : Using themethod of replacing CaCO3 coating by CaCO3 nanomaterials with different proportions in traditional paint formulas, the experiment is performed on tin plate and measuring, analyzing, evaluating the durability indexes according to time. Methods of analyzing properties of paint films based on Vietnamese standards used to measure the properties of paint films. Findings: Replacing CaCO3 coating material with CaCO3 nanomaterial has increased the superiority of alkyd paint to protect metals. The higher the replacement rate, the higher the measure of the properties of the paint film, the impact increased by about 13% (70 to 79 kg.cm), Glossy 600 increased by about 10%, Glossy 850 increased by about 9%. Especially, the durability of paint film over time is nearly double when completely replace the CaCO3 coating with CaCO3 nanomaterials. However,CaCO3 nanomaterials are much more expensive than CaCO3 so in practice they should only replace less than 8% by weight. For projects requiring high quality, a higher rate may be used. Novelty/Applications: The novelty of the study is the replacing CaCO3 with Nano CaCO3; this replacement confirms the effectiveness of nanomaterials and helps paint manufacturers choose the replacement rate suitably.

Keywords: Adhesion; coatings; durability; glossiness; impact level; long life

© 2020 Hai et al.This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee).

Subscribe now for latest articles and news.