Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 26, Pages: 2206-2214

Original Article

Ganesh S Ingle1*

1Associate Professor, School of Civil Engineering, Dr. Vishwanath Karad MIT World Peace University, Pune, 411038, India

*Corresponding Author

Email: [email protected]

Received Date:29 May 2021, Accepted Date:15 July 2021, Published Date:30 July 2021

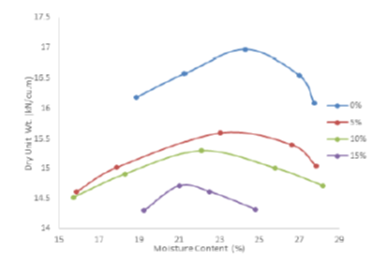

Objectives: To determine the strength and swelling behavior of black cotton soil (expansive soil) using a shredded rubber tyre as an additive. Methods: Series of unconfined compressive strength and California Bearing Ratio (CBR) tests were carried out on black cotton soil mixed with 0%, 5%, 10%, and 15% of shredded rubber tyres, and the results were compared with untreated soil samples. The study also investigated the influence of shredded rubber on swelling characteristics of black cotton soil by performing the swelling pressure test. Findings: From the experimental results, it is inferred that the optimum addition of a 10% shredded rubber tyre can effectively improve the strength behavior of black cotton soil. The unconfined compressive strength and California Bearing Ratio (CBR) of soil stabilized with 10% of shredded rubber tyre increased by 32 % and 49.3% respectively as compared to the untreated soil. An illustration presented shows the effect of increased CBR in terms of the reduction of 18% pavement thickness. This may reduce the total cost of the project. The present study also investigated the swelling potential of Black cotton soil and it is found to be decreased by 33.33% for the addition of 15% shredded rubber soil as compared to untreated soil. Novelty: The use of shredded rubber in expansive soil increased its CBR value, leading to a reduction in 18% of pavement thickness. Hence, it may lead to a further reduction in the total cost of the project. Also, the disposal problem of waste rubber tyres is resolved up to a certain extent.

Keywords: Shredded Rubber Tyre; Black Cotton Soil; Unconfined Compressive Strength; California Bearing Ratio; Soil Stabilization

© 2021 Ingle. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.