Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 20, Pages: 1647-1660

Original Article

K Ashwini✉ 1 , P Srinivasa Rao 2

Received Date:22 April 2021, Accepted Date:21 May 2021, Published Date:04 June 2021

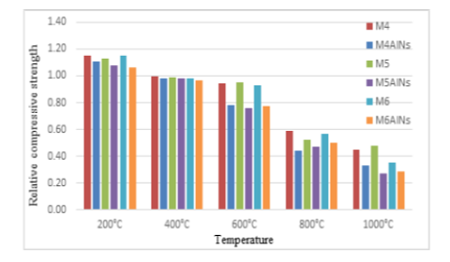

Objectives: To investigate the influence of adding alccofine and nano-silica as an additive on the behavior of concrete at elevated temperatures. Methods: Concrete specimens with and without nano-silica and alccofine were heated to temperatures of 200ºC to 1000ºC for 4, 8, and 12hours. In this study, relative compressive strength and ultrasonic pulse velocity were investigated. Using regression analysis, a relation between compressive strength and temperature was derived and compared with other relations. Findings: The outcomes demonstrated that elevated temperatures degraded the microstructure of concrete and reduced the relative compressive strength and ultrasonic pulse velocity. The percentage of degradation was higher in nano-silica and alccofine concrete at 1000ºC. The proposed relation was found accurate compared to other relations. Novelty/Applications: As the temperature increases above 600ºC, control mixes performed better than the concrete mixes using nano-silica and alccofine.

Keywords

concrete, alccofine, nanosilica, fire resistance, ultrasonic pulse velocity

© 2021 Ashwini & Rao. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.