Indian Journal of Science and Technology

Year: 2023, Volume: 16, Issue: 26, Pages: 1975-1985

Original Article

Yamini J Patel1*, Niraj Shah2

1Assistant Professor in Applied Mechanics Department, Vishwakarma Government Engineering College, Visat Gandhinagar Highway, Chandkheda, Ahmedabad, Gujarat, 382424, India

2Dean, School of Engineering, P. P. Savani University, Kosamba, Surat, 394142, Gujarat, India

*Corresponding Author

Email: [email protected]

Received Date:22 April 2023, Accepted Date:17 June 2023, Published Date:04 July 2023

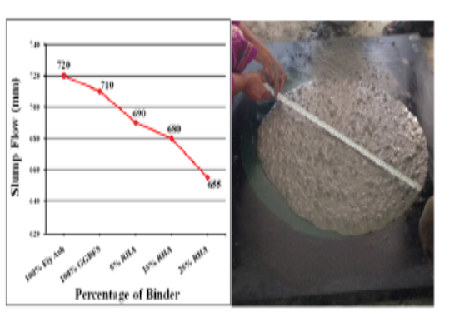

Objectives: To investigate the effect of replacement of Rice Husk Ash (RHA) on the workability and compressive strength of Self Compacting Geopolymer Concrete (SCGC) blended with Ground Granulated-Blast Furnace Slag (GGBFS) for sustainable environment. Methods: GGBFS as an industrial waste and RHA as an agricultural waste were used as an aluminosilicate source materials for the development of SCGC. Use of RHA is popular for their considerable effects on the mechanical as well as microstructural properties of cement based binders as well as geopolymer binders. The SCGC mixes were prepared by replacing GGBFS with RHA at various proportions of 5%, 15% and 25%. The fresh properties of SCGC have assessed through “Slump Flow, V- funnel, L-Box and J-Ring test methods as per EFNARC” guidelines. Findings: Partial replacement of RHA decreases the workability. Replacement of RHA in SCGC beyond 5% reduces the compressive strength, yet the target strength (30MPa) of all mixes were achieved. SEM analysis with EDXS spectra shows the dense microstructure of optimum mix with 5% RHA replacement. The 28 days strength of 42.6 MPa for 5% RHA, 39.31MPa for 15% RHA and 31.59 MPa for 25% RHA were achieved at ambient temperature, which is 110%, 94% and 56% higher than control mix strength (MF-100% FA) at ambient temperature. Novelty: SCGC is a new concrete which fulfill the properties of both Geopolymer (GPC) and Self Compacting Concrete (SCC). Most of the investigations in SCGC have been performed using Fly Ash, Metakeoline, and GGBFS as a binder. In this experimental study, GGBFS as an industrial waste and RHA as an agricultural waste are used as source material to develop the SCGC.

Keywords: Sodium Silicate; Sodium Hydroxide; Fresh Concrete; Rice Husk Ash; Microstructure; Self Compacting Geopolymer Concrete

© 2023 Patel & Shah. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.