Indian Journal of Science and Technology

Year: 2021, Volume: 14, Issue: 9, Pages: 765-775

Original Article

Md. Tanvir Hossen1*, Tarikul Islam1, Emdadul Islam Mahee2, Zarin Tasnim Reza3, Mahbubur Rahman4, Md. Sultan Mahmud5

1Department of Textile Engineering, Jashore University of Science and Technology, Jashore-7408, Bangladesh

2Assistant Manager, Technical and Marketing, Texxet International, Dhaka, Bangladesh

3Department of Fashion Design, BGMEA University of Fashion and Technology, Bangladesh

4Department of Textile Engineering, Mawlana Bhashani Science and Technology University, Tangail-1992, Bangladesh

5Department of Yarn Engineering, Bangladesh University of Textiles, Dhaka, Bangladesh

*Corresponding Author

Email: [email protected]

Received Date:19 December 2020, Accepted Date:09 March 2021, Published Date:19 March 2021

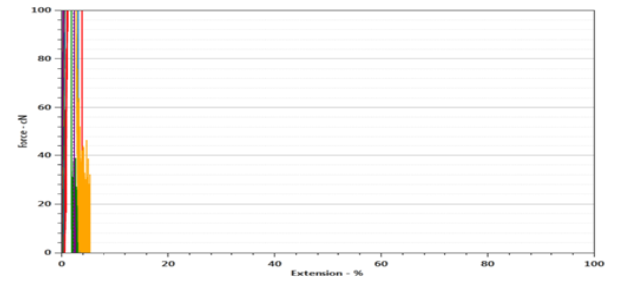

Objectives: The objectives of this research is to investigate the physicomechanical characteristics of okra bast fibres (OBF) as well as to go through all the process to make this okra fibre as one of the commercial cellulosic fibres which can be used in different textile applications such as reinforcements in polymer matrix composites, carpets, materials used for absorbing oils and liquids, packaging industries, basic textiles products, coarse decorative textile products, Geo-textiles etc. all over the world. Methodology: In this work, OBFs are characterized by using Fourier transform infrared spectroscopy (FTIR), Breaking strength and breaking extension test, linear density analysis, Microscopic view and Scanning electron microscopy (SEM) analysis, and the crystallinity is measured by X-Ray Diffraction (XRD) data. Findings: XRD data indicates that the amorphous region is far greater than the crystalline region in OBFs, SEM analysis displays the technical fibres are overlapped and cemented by non-cellulosic compounds. These test results show a great similarity to other bast fibres properties mainly physical, mechanical, microstructural (crosssectional and longitudinal view) properties.

Keywords: Okra bast fibre (OBF); SEM; FTIR; XRD; Breaking strength and breaking extension; Linear density

© 2021 Hossen et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.